Frequently Asked Questions

Emblaser Questions

Where can I buy the Emblaser 2?

Check our list of authorised distributors and resellers here:

What is the difference between the Emblaser 2 and Core?

|

|

|

| Emblaser 2 | Emblaser Core | |

| Dimensions | ||

| External Dimensions | 720mm x 540mm x200mm | 720mm x 530mm x 230mm |

| 28.35" x 21.25" x 7.8" | 28.35" x 20.86" x 9.0" | |

| Material Capacity (metric) | 500mm x 300mm x 50mm | 500mm x 300mm x 50mm |

| 19.66" x 11.81"x 1.97" | 19.66" x 11.81"x 1.97" | |

| Weight | 12 kg | 6 kg |

| 26.46 lb | 13.23 lb | |

| Setup | ||

| Requires assembly | N | Y |

| Fully assembled & tested | Kit requires assembly | |

| Laser | ||

| Focusing | Auto-Focus | Auto-Focus |

| Laser Type | Solid-State Diode | Solid-State Diode |

| Laser Power | Equivalent to 15-20watt CO2 laser | Equivalent to 15-20watt CO2 laser |

| Beam Spot Size | 0.2mm | 0.2mm |

| Laser Classification | Class 1 | Class 4 |

| Cooling | Internally Air-Cooled | Internally Air-Cooled |

| Hardware | ||

| Material Pass-thru | N | Y |

| Automatic Laser Height Control | Y | Y |

| Workspace Camera | Y | Y (optional) |

| USB Connectivity | Y | Y |

| WiFi Connectivity | Y | Y |

| Internal workspace lighting | Y | N |

| Air-Assist | Y | Y (optional) |

| Built-in Fume extraction fan | Y | N |

| Connecton for exhaust hose | Y | N |

| Fume Extractor ready | Y | N |

| Safety Features | ||

| Safety Lid Interlocks | Y | N |

| Fire Rated Enclosure | Y | N |

| Optical & Fire rated lid | Y | N |

| Material Ignition Alert | Y | N |

| Software | ||

| LightBurn License | Included | Included |

| License Type | Never Expires, 3 years of updates | Never Expires, 3 years of updates |

| Windows, Mac, Linux | Y | Y |

| Electrical | ||

| Requirements | 110/240 VAC, 50-60HZ | 110/240 VAC, 50-60HZ |

| Consumption | Peak 65W. Less than an average light globe. | Peak 65W. Less than an average light globe. |

| Warranty | ||

| Mechanics & Electronics | 12 months | 12 months |

| Laser Diode | 3 year | 3 year |

What else do I need to buy to use my Emblaser?

All Emblaser machines come with everything needed to start creating laser cut or engraved works of art!

You just need a computer to run the software, materials and your imagination!

Get inspired with our free projects.

Projects

What thickness can it cut?

This all depends on the material and it’s properties.

Check the table below for some of the common material thicknesses:

Emblaser 2 & Core Supported Materials

| SUPPLIER | CATAGORY | MATERIAL | PART NUMBER | CUT (mm) | ENGRAVE | COMMENTS |

|---|---|---|---|---|---|---|

| Generic | ||||||

| Fabric | Cotton | 3 | Y | |||

| Fabric | Felt (Natural) | 6 | N | All colors except white. | ||

| Fabric | Felt (Synthetic) | 6 | N | |||

| Fabric | Denim | 1 | Y | |||

| Fabric | Felt (Adhesive Backed) | 1 | N | |||

| Leather | Leather (Vegetable Tanned - Brown) | 3 | Y | Treatment & color dependant. Air-Assist recommended. | ||

| Metal | Anodised Aluminium | - | Y | |||

| Metal | Stainless Steel | - | Y* | *Engraving possible with coating (see Spectrumark) | ||

| Other | Slate | - | Y | |||

| Paper / Card | Corrugated Cardboard | 6 | Y | |||

| Paper / Card | Pasteboard | 2.6 | Y | |||

| Paper / Card | Card (350gsm) | 1.25 | Y | |||

| Plastic | Acrylic (Green, Red, Yellow,Black) | 3 | Y | |||

| Plastic | Acrylic (Blue) | - | Y | |||

| Plastic | Acrylic (Transparent / White) | - | Y* | *Engraving possible with coating. | ||

| Plastic | Polypropylene (Black, Red, Yellow, Green) | 1 | Y | Air-Assist required. | ||

| Plastic | Polypropylene (Blue) | N | N | |||

| Rubber | Synthetic Rubber | 2 | Y | |||

| Wood | Plywood (Generic) | 3 | Y | |||

| Wood | Plywood (Bamboo) | 3 | Y | |||

| Wood | Plywood (Jarrah) | 3 | Y | |||

| Wood | Balsa | 6 | Y | |||

| Wood | Hardwood Oak | 2 | Y | |||

| Wood | MDF | 3.0* | Y | *Cutting dependant on composition and moisture content. | ||

| Wood | Corkboard | - | Y | Air-Assist required. | ||

| Darkly Labs ECM Range | ||||||

| Plastic | Laser Contact Film (Blue) | DL-ECM-CFBLU | 0.2 | N | **Only ECM range safe for laser cutting. | |

| Plastic | Laser Contact Film (Yellow) | DL-ECM-CFYELL | 0.2 | N | **Only ECM range safe for laser cutting. | |

| Plastic | Laser Contact Film (White) | DL-ECM-CFWH | 0.2 | N | **Only ECM range safe for laser cutting. | |

| Plastic | Laser Contact Film (Black) | DL-ECM-CFBLK | 0.2 | N | **Only ECM range safe for laser cutting. | |

| Plastic | Laser Contact Film (Red) | DL-ECM-CFRED | 0.2 | N | **Only ECM range safe for laser cutting. | |

| Plastic | Laser Contact Film (Light Blue) | DL-ECM-CFLTBLU | 0.2 | N | **Only ECM range safe for laser cutting. | |

| Wood | Plywood (Poplar-Laser) | DL-WPP30, DL-WPP60 | 6 | Y | ||

| Wood | Plywood (Eucalypt-Laser) | DL-WEP10, DL-WEP25 | 2.5 | Y | ||

| Rowmark | ||||||

| Plastic | Ply-Acrylic (Matte Black - Brass) | TROPHYFLEX LZ417015 | 0.7 | Y | ||

| Plastic | Ply-Acrylic (Br. Copper - Black) | TROPHYFLEX LZ894-015 | 0.7 | Y | ||

| Plastic | Ply-Acrylic (Br. Silver - Black) | LASERLIGHTS S63-1224 | 0.3 | Y | ||

| Plastic | Ply-Acrylic (Br. Gold - Black) | FLEXIBRASS 602-734 | 0.7 | Y | ||

| Plastic | Ply-Acrylic (Br. Gold - Black) | LASERMAX METALS LM922-734 | 1.5 | Y | ||

| Plastic | Ply-Acrylic (Br. Steel - Black) | METALGRAPH PLUS MP922-314 | 1.5 | Y | ||

| Plastic | Ply-Acrylic (Natural Teak - Brown) | THE NATURAL TN922-178 | 1.5 | Y | ||

| Plastic | Ply-Acrylic (White - Black) | LASERMAX LM922-204 | 1.5 | Y | ||

| Plastic | Ply-Acrylic (Red - White) | LASERMARK 922-602 | 1.5 | Y | ||

| Plastic | Ply-Acrylic (Blue - White) | TEXTURES 822-503 | - | N | ||

| Plastic | Ply-Acrylic (Desert Sand - Black) | TEXTURES 822-854 | 1.5 | Y | ||

| Plastic | Ply-Acrylic (Mattle - Br. Aluminium) | (Reverse Lasermak 922-361 | 1.5 | N | ||

| Plastic | Acrylic Red - Cast Sand Texture | ColorHues CH341-631 | 2.8 | Y | ||

| Plastic | Acrylic Green | 2 | Y | |||

| Wood | Plywood (Mahogany) | RW1224125MAH | 3.2 | Y | ||

| Wood | Plywood (Red Alder) | RW1224125ALD | 3.2 | Y | ||

| Wood | Plywood (Maple) | RW1224125MAP | 3.2 | Y | ||

| Wood | Plywood (Walnut) | RW1224125WAL | 3.2 | Y | ||

| Wood | Plywood (Colorshop Woods Range) | All | 3 | Y |

List of materials tested and supported on the Emblaser 2 & Core.

What is the warranty on an Emblaser?

Emblaser 1 Warranty

- 12 mths on all components

Emblaser 2 & Emblaser Core Warranty

- 12mth warranty on mechanical and electrical components

- 3 year warranty on Laser diode

Accessory Questions

Cutting Tray Questions

Q: Do you need to use the Silicon Mats when using the Metal Cutting Tray?

A: No. The cutting tray replaces the silicone cutting mats.

Q: Will the base plate get damaged/marked by using the Cutting Tray?

A: No.

Q: Can I perform the Focus Calibration with the Cutting Tray?

A: No. At this point this calibration needs to be performed using the cutting mats.

Q: What settings do I need to change in LightBurn when using the Cutting Tray?

A: You need to set the ‘Support Height’ to 26mm

Q: Do I need to wash the Cutting Tray?

A: No. Although the tray will become discoloured over time, removing cutting debris is all that is needed.

What is Air-Assist?

Air-Assist is a device that injects high pressure air at the point where the laser is cutting. This air flow helps product a much cleaner cut and also acts as a safety feature to extinguish small material flames.

The Emblaser 2 is fitted with air-assist.

What does ECM 'Emblaser Certified Materials' mean?

ECM or ‘Emblaser Certified Materials’ are approved to be safely used for laser cutting or engraving with the Emblaser range.

Darkly Labs have extensively tested the materials in their machines confirming they perform well and also provide the MSDS (Material Safety Data Sheet) for these materials.

We always recommend checking any material is safe before using it in a laser machine. Using unsafe materials may result in serious illness, machine damage or fire.

Technical Questions

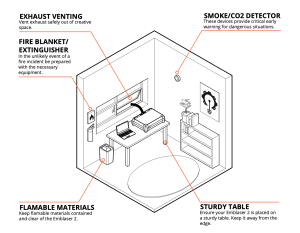

What are the safety considerations when using a laser cutter?

| What is your machine's Laser Class? | Laser cutters receive a 'Class' rating depending on their power and safety features. A 'Class 1' laser is the safest and can be used without PPE. | Emblaser 2 has a 'Class 1' rating. |

| Never run any laser cutter unattended | Laser cutting can sometimes cause materials to ignite. Left unattended, this could cause a serious fire. | Emblaser 2 is made from a fire rated enclosure. If a material was to ignite, the machine would contain the fire. |

| Does your machine have Safety Interlocks? | Safety interlocks prevent users from accidentally interacting with the laser itself. The most common interlock is to disable the laser if the lid is opened. | Emblaser 2 machines contain lid interlocks. |

| Have you considered Fire Safety? | A smoke detector, fire extinguisher and fire blanket are handy itens to have in your workspace. | All Emblaser machines ship with a fire blanket. |

| Are your materials safe to laser? | Is's important to know what the material is you are cutting. Some materials are dangerous when laser cut. For instance, any material containing Chlorine produces extremely toxic fumes. |

|

| Have you considered fumes? | Laser cutting produces fumes. Ensure you are able to safely vent the fumes produced. | The Emblaser 2 includes an in-built exhaust fan and is supplied with an exhaust hose. You can also use the F2000 Fume extractor to fully filter fumes. |

| Does your machine need supervision? | Consider who will have access to your laser cutter. Do they need supervision? |

How do I troubleshoot a problem?

There are a number of ways to do this.

Check the ‘Troubleshooting & Maintenance Guides’ in our Help Centre.

Help Centre

Check our online Community or post a question there.

Community

Contact us directly.

Contact Us

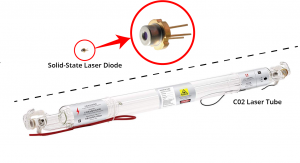

What is the difference between a Diode and CO2 laser?

All Emblaser machines are designed around Solid-State Laser Diodes technology.

| Solid-State Laser Diode | CO2 Laser Tube | |

|---|---|---|

| Laser component size | Very small and compact. | Large. |

| Robustness | Very durable against bumps and knocks. | Made from glass. Very delicate. |

| Lifespan | For Emblaser machines, 5000-7000hrs. | Machine dependant. As little as 500 hrs. |

| Cooling | Many options possible, such as air or liquid cooling. Emblaser machines can run continuously without cool-down period. | Must be liquid cooled. Recommended to have liquid cooling system with Chiller for continuous use. |

| Shelf Life | none | Limited shelf life as tubes degrade over time. |

| Energy Use | Very efficient: Emblaser 2 uses approx. 65W of energy use. | Very inefficient. Co2 machines start around 500W of energy use. |

| Machine complexity | Low. Fewer parts required. | More optical components are needed to control path of laser beam. This adds complexity and calibration. |

| Portable | Yes | No. Optical system susceptible to mis-alignment. |

| Works on transparent materials | No | Yes |

| Maintainance | Few components to calibrate and keep clean. | More components to calibrate and keep clean. |

Why can't it cut transparent materials?

The Emblaser range use a solid-state diode laser system which has many advantages. Unfortunately one of the drawbacks is that it cannot cut transparent materials.

This is a result of the frequency of laser light produced, which basically passes directly through transparent materials, without affecting them.

Although transparent materials cannot be cut, there are very simple techniques that allow them to be engraved. Have a look at this project for an example:

What is the lifespan of my laser diode?

Emblaser 2 & Core laser diodes have lifespans of 5000-7000 hours.

Unlike CO2 laser tubes, they do not contain gasses that degrade over time. This means laser diodes do not have a shelf life when not being used.