Laser cutters have become indispensable tools for numerous industries and hobbyists alike, offering precise and efficient cutting capabilities. However, when it comes to material selection for laser cutting, caution must be exercised, particularly with materials containing chlorine. While these materials may seem harmless, they can pose serious risks to both the equipment and the health of users. Understanding the dangers associated with chlorine-based materials is crucial for ensuring safe and efficient laser cutting operations.

Corrosive Effects:

Chlorine-based materials, such as polyvinyl chloride (PVC), release hydrochloric acid when exposed to high temperatures. This acid is highly corrosive and can damage the delicate components of laser cutters, including lenses, metals and electronic components. The resulting corrosion can significantly reduce the lifespan of the equipment and compromise its performance.

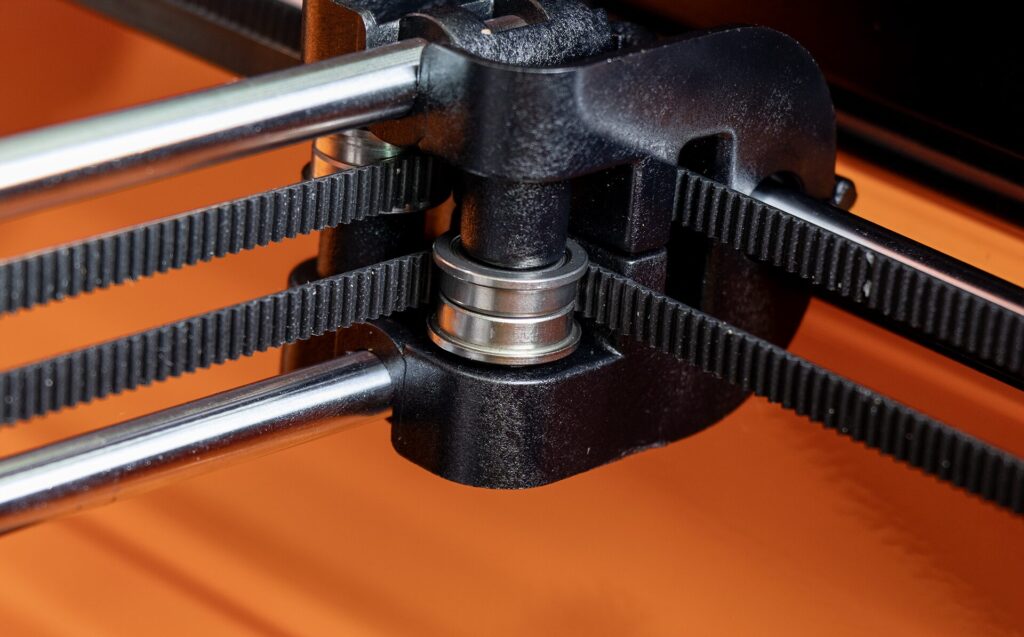

New bearings, belts and rails from the Emblaser 2.

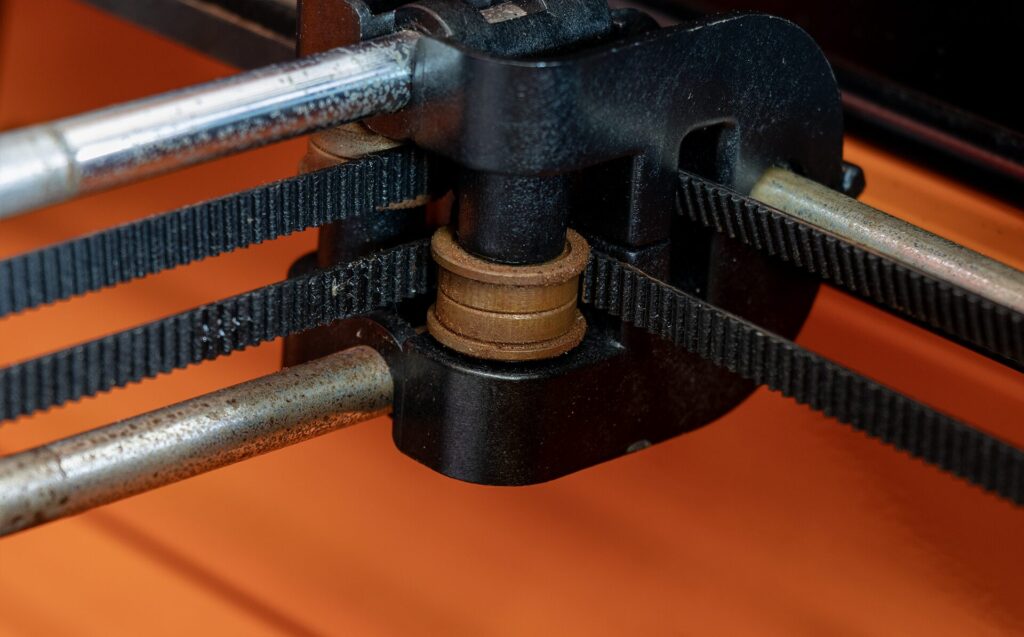

Parts exposed to chlorine fumes for 5 minutes.

Toxic Fumes:

When chlorine-based materials are subjected to laser cutting, they emit toxic fumes, including chlorine gas and dioxins. Inhalation of these fumes can lead to respiratory problems, eye irritation, and skin allergies. Prolonged exposure to chlorine gas may even cause severe health issues, including damage to the respiratory system and internal organs.

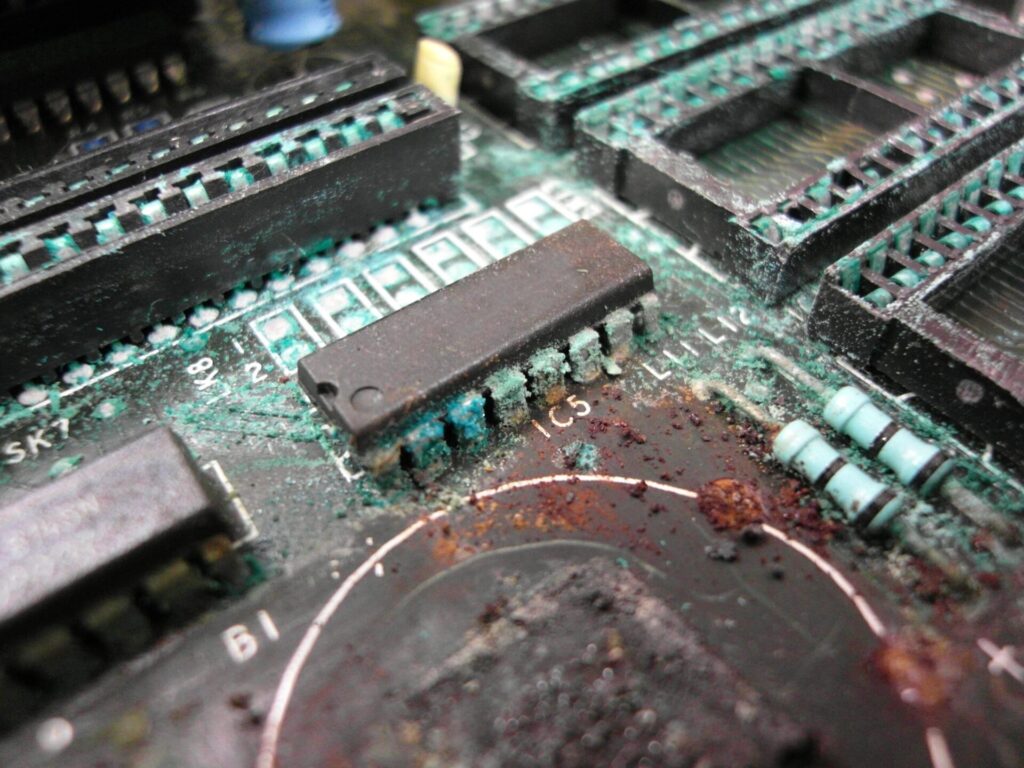

Equipment Contamination:

Chlorine-based materials can leave residue and deposits on the internal components of a laser cutter. These deposits not only impair the machine’s performance but can also lead to short circuits, electrical failures, and even fires. Additionally, the presence of chlorine residues can adversely affect the quality of future laser cutting projects.

Electronic components subject to corrosion.

Environmental Impact:

Chlorine-containing fumes released during laser cutting are harmful to the environment. Dioxins, in particular, are persistent organic pollutants known for their detrimental effects on ecosystems and human health. Their release into the atmosphere contributes to air pollution and poses long-term risks to environmental sustainability.

WatchDog to the Rescue:

The WatchDog accessory, designed for the Emblaser Pro, features a highly sensitive chlorine fume sensor capable of detecting even minimal levels of chlorine. Upon detection, the WatchDog system activates immediately, emitting an audible alarm. Concurrently, it disables the laser system and sends a warning message to the LightBurn software. This alert informs users of the hazardous conditions and provides guidance on the next steps to ensure safety.

Conclusion:

While laser cutting offers incredible precision and versatility, the dangers associated with chlorine-based materials should not be underestimated. To ensure the safety of users, extend the lifespan of equipment, and minimize environmental impact, it is crucial to avoid using materials containing chlorine in laser cutters. By opting for chlorine-free alternatives and using the Emblaser Pro WatchDog, users can enjoy the benefits of laser cutting while safeguarding their health, equipment, and the environment.