Laser Cutting for Beginners

What is a Laser Cutter ?

A laser cutter is a creative tool that uses a very focused beam of laser light to cut through or engrave onto materials. The high power beam of light is focused to a very fine point, thinner than a human hair, allowing very accurate cutting and engraving to be achieved. Laser cutters are considered a CNC (Computer Numeric Controlled) machine and rely heavily on their control systems and software to operate correctly.

What do I need to start Laser Cutting ?

Generally you will need the following items:

A Laser Cutting Machine

This sounds obvious, but do your homework and make sure you consider everything you need to use your machine. Software, Cooling System, Materials, Technical Support etc.

Emblaser machines come with everything you need to start laser cutting & engraving.

Laser Cutting Software

Laser cutting software is the link between you and your laser cutter.

Not all laser software is created equal and could be the difference between a smooth or frustrating experience when using your machine. Make sure you research this before choosing your laser cutter.

All Emblaser machines include a fully licensed copy of LightBurn, the most powerful and intuitive laser cutting & engraving software on the market.

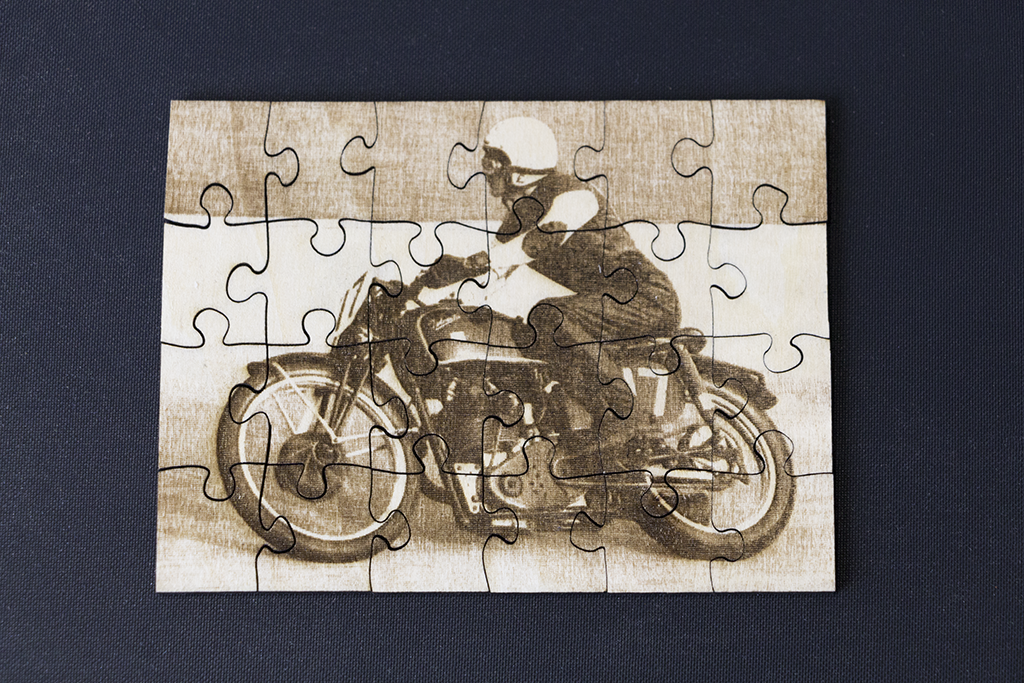

Materials to Cut and Engrave

You will need materials to cut and engrave.

Not all materials can be laser cut, so determine what you plan to work with and discuss this with your laser cutter vendor.

The Emblaser will work on a very wide range of materials. If you are unsure about your specific material, please contact us to discuss.

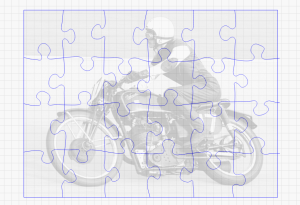

Design Files

Design files instruct your laser machine on what it needs to do.

Easily create your own designs in the LightBurn software or can get inspiration from our free projects.

How do I use a laser cutter ?

To use a laser cutter you need a design file and material to cut or engrave.

A design file can be as simple as a downloaded image or as complex as a design you have created using design software.

Emblaser laser cutters work with many file formats including images (jpg, png, bmp etc) to vector files from design software such as (pdf, ai etc) all the way to CAD design files such as (dxf, dwg etc).

What about safety?

There are several important considerations before deciding on a laser cutting machine. Check the topics listed below:

What laser 'class’ is the machine?

Laser cutters receive a ‘Class’ rating depending on their power rating and safety features.

Class I is the safest laser and can be used without the need for protective eyewear and PPE. Other classes of machine may pose safety risks that need to be carefully addressed.

The Emblaser2 is a Class 1 rated laser cutter.

Is my material safe to laser?

Not all materials a safe to laser cut or engrave. It’s important to know what the material is you are planning to use.

For instance, any material containing Chlorine produces extremely toxic fumes.

If you are unsure, please email us to check.

How are fumes produced by the laser cutting process handled?

Laser cutting produces fumes that must he safely handled.

The Emblaser2 has an inbuilt exhaust fan and exhaust hose. A dedicated fume filter is also available.

What additional safety features are available with the machine?

Laser machines can use include safety features to prevent injury to the user. The most common are interlocks that prevent the use from accidentally interacting with the laser beam.

The EmblaserPro and 2 includes lid interlocks that turn off the laser when the lid is opened. It’s also made from a fire rated enclosure and includes a material ignition alert system . All Emblaser machines ship with a fire blanket in the event of a mishap.

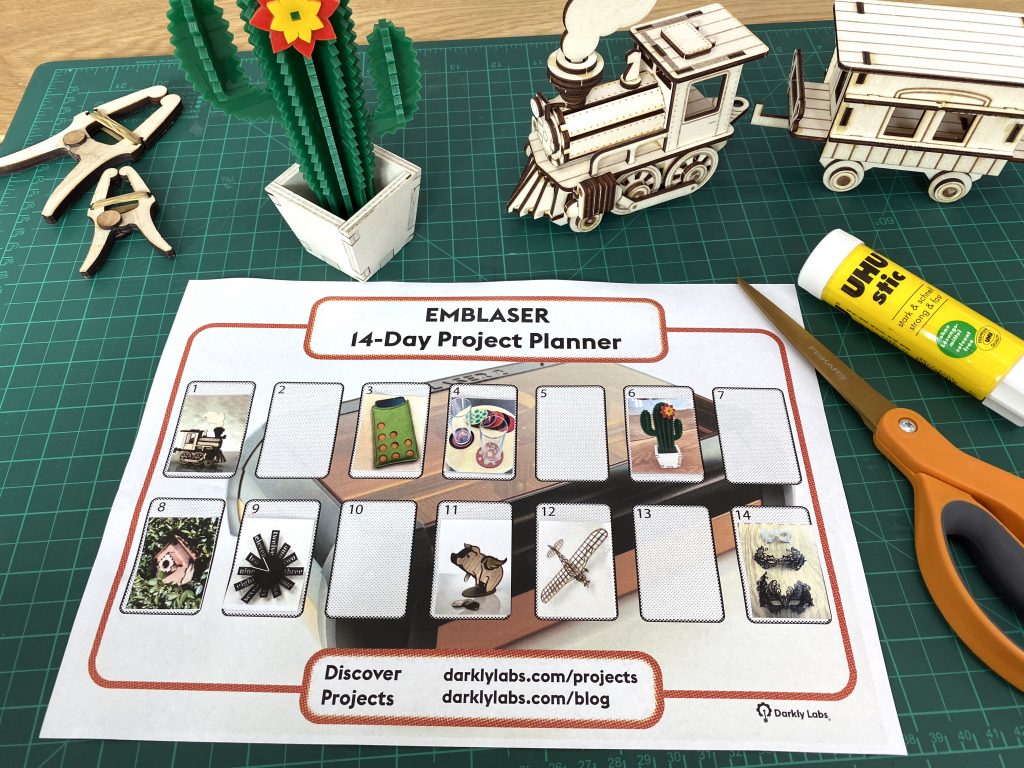

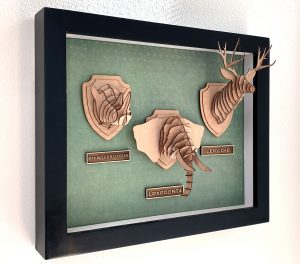

What can I do with my laser cutter?

Your Emblaser machine will allow you to create virtually anything. To help you get you started, Darkly Labs offers a variety of projects guides. The guides available on the Darkly Labs site range in difficulty and complexity to ensure all skill levels are catered for.

For Classroom use, the main focus is the overall safety of students and teachers whilst using any of the Emblaser, hence each of the guides you see below have been rigorously trialed to ensure that they are easily repeated and safe to follow.