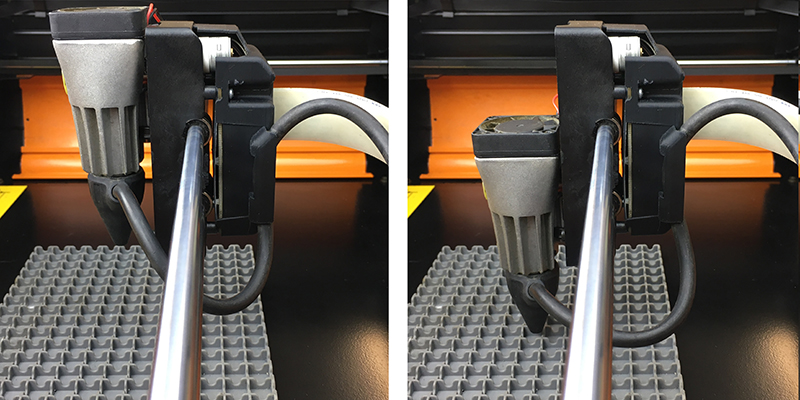

This article will detail the lens cleaning process for the Gen1 / Rev1 type of Lens Unit.

If you are unsure which type of Lens Unit you have, please check this article: LINK.

Required:

Note: All of the items below are supplied with the lens cleaning kit.

- 1.5mm Hex tool

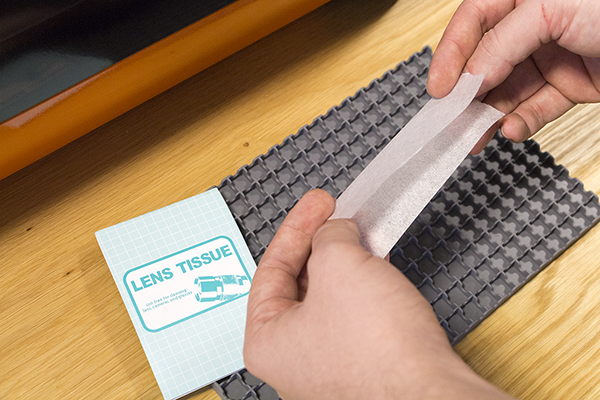

- Lens Tissues

- Lens Cleaning Wipes

- Lens Removal Tool

- LensPen

- A clean workspace free of dust and debris.

Step 1:

Place a cutting mat under the laser carriage.

Using the X and Y position controls in LightBurn, move the laser carriage to the centre of the workspace. Then using the Z position controls, lower the laser unit to its lowest possible position.

NEVER force the laser unit manually as this can damage the motor and gearbox.

Step 2:

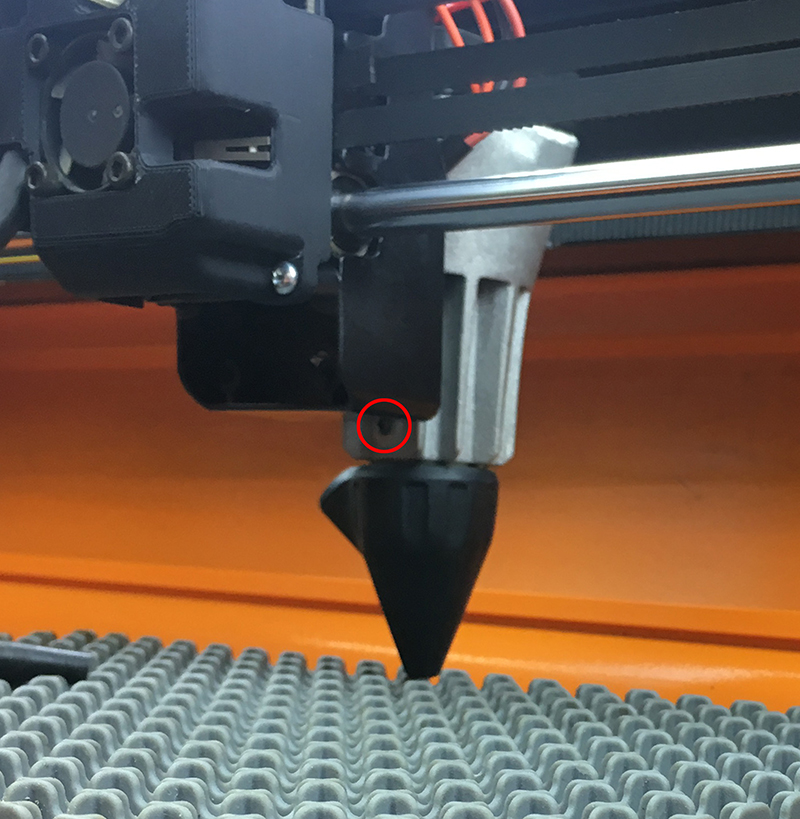

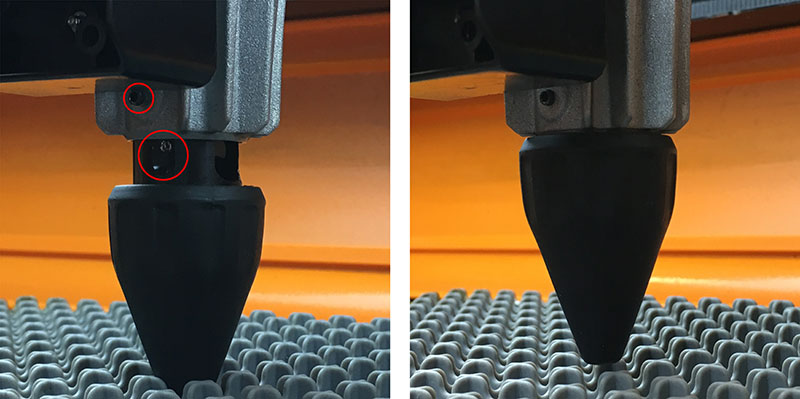

Locate the small set screw on the back of the laser heatsink.

Use the 1.5mm Hex tool to carefully loosen the setscrew until the lens housing comes free.

Using the Z position controls in LightBurn, raise the laser unit and withdraw the Lens Housing.

Step 3:

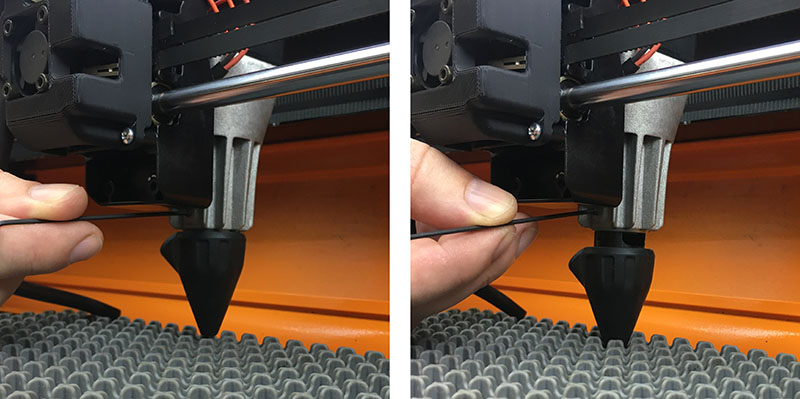

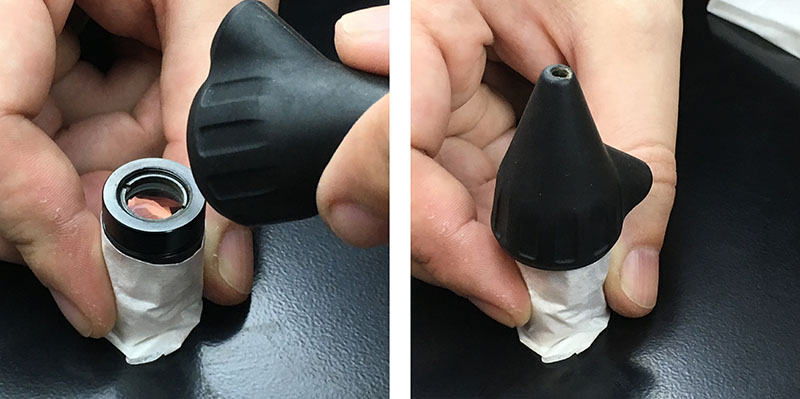

IMPORTANT: Be very careful to not touch any of the glass surfaces of the lens unit. This can cause the optics to degrade over time.

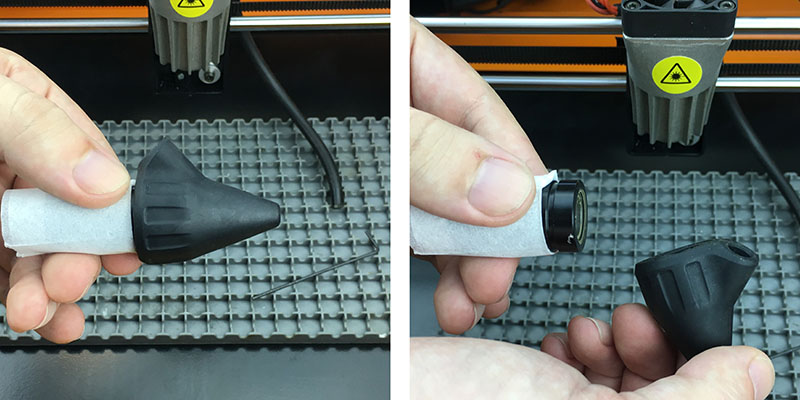

It is safe to handle the Lens Housing by the Aperture Nozzle.

The lens housing is very delicate, especially the glass surfaces. Be extremely careful to not touch these surfaces.

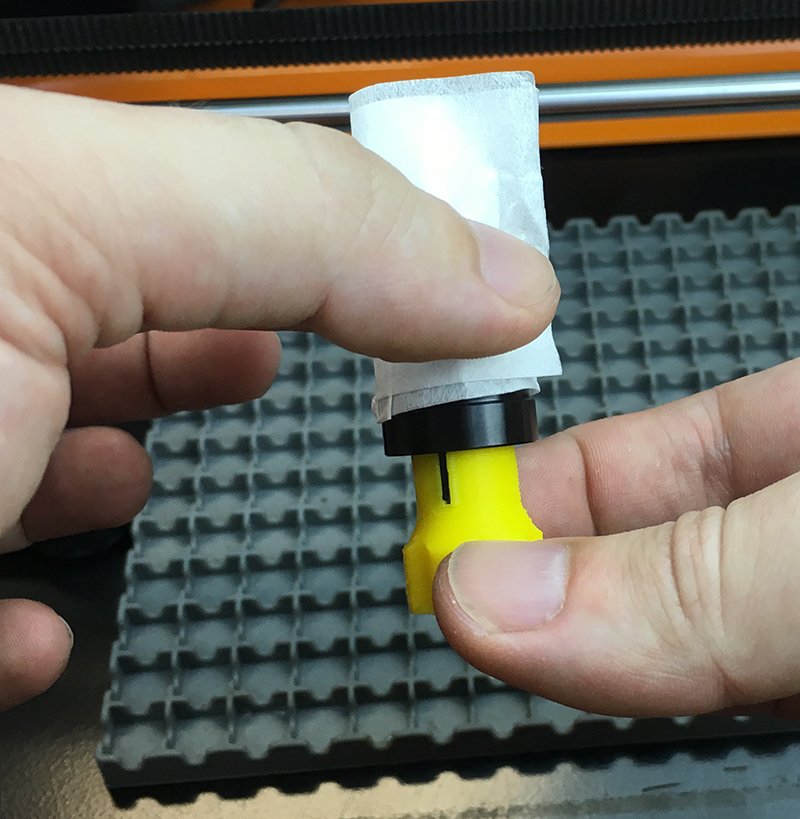

Before removing the Aperture Nozzle from the Lens Housing, fold a piece of lens tissue in half and use it to wrap around the Lens Housing to protect the glass parts.

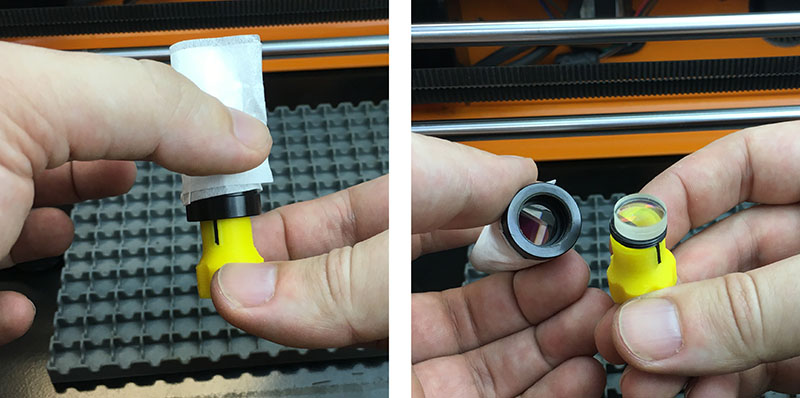

Once the lens housing is safely wrapped up, remove the Aperture Nozzle.

Step 4:

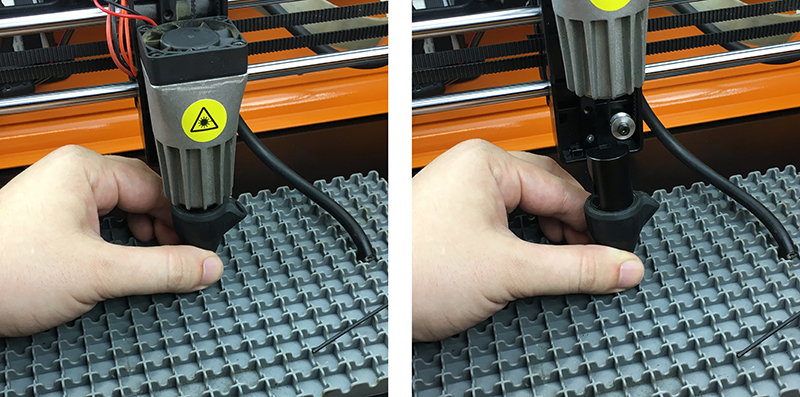

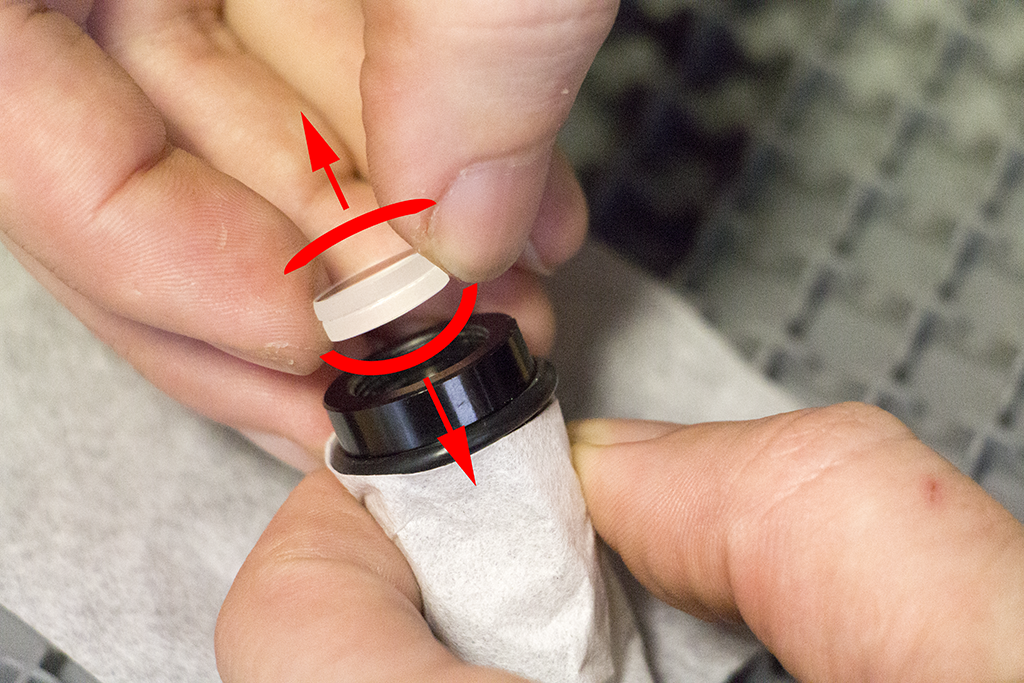

Using your lens removal tool, carefully unscrew the retaining ring which holds the lens in place.

The Lens Removal tool will bend if you turn it with too much force to avoid damaging your lens. If the black insert in the Lens Removal tool wears out, replacements can be found in your tool kit.

Step 5:

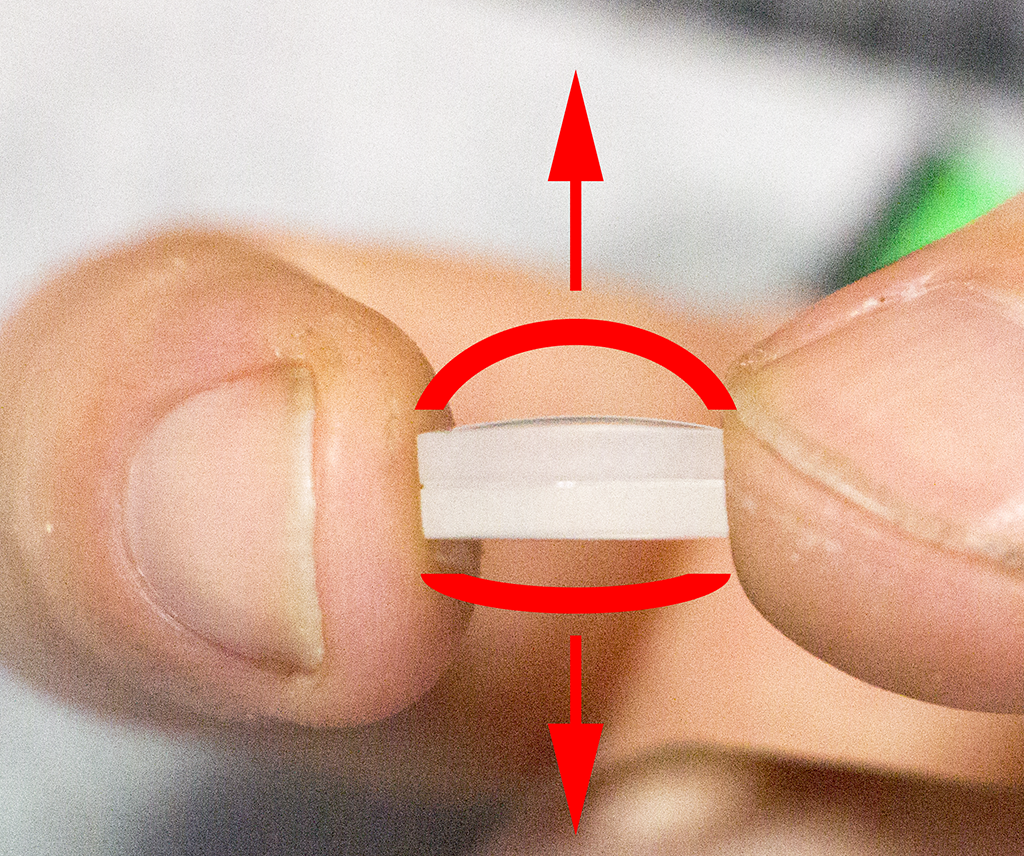

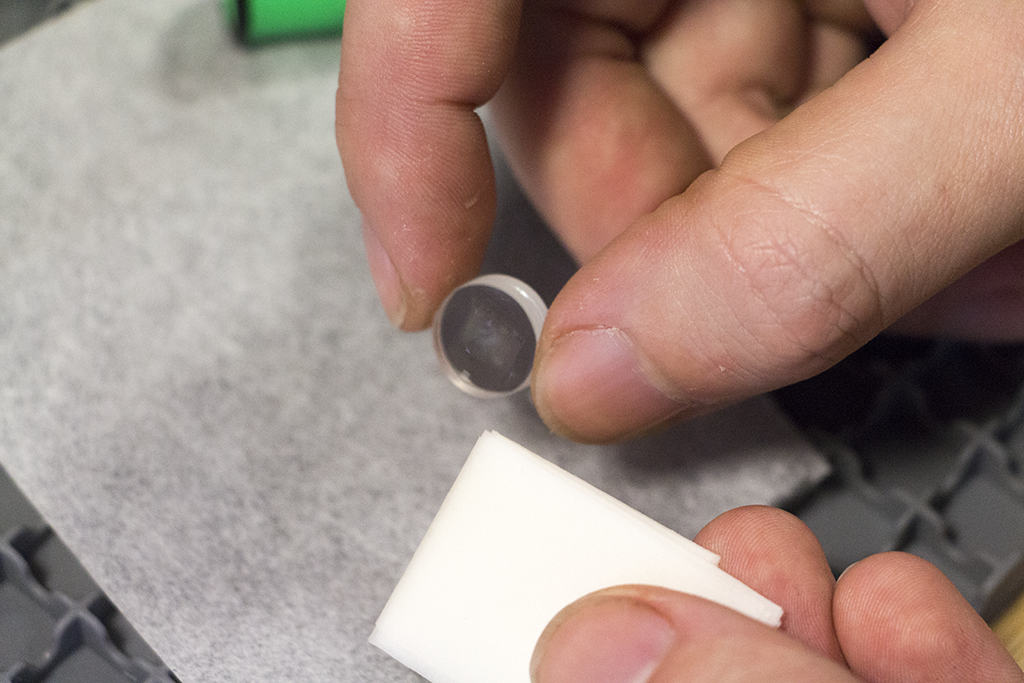

Always hold the lens by its sides. Never touch the clear lens surfaces with your fingers. These surfaces are delicate and critical to the performance of your machine.

Note that one side of the lens is more curved. It is important to pay attention to this when re-installing your lens.

As seen in the photo, the more curved surface points upwards. The less curved surface should face out of the lens housing and towards the baseplate.

Step 6:

Using a fresh lens wipe, carefully clean the lens surfaces. Be gentle and check carefully to ensure any residue on the lens has been removed.

Step 7:

Insert the lens back into the Lens Housing. Refer to Step 5 the orientation of the lens and its curved surfaces. This is critical to the correct performance of your machine.

Carefully screw on the retaining ring, avoid over tightening.

Step 8:

Reattach Aperture Nozzle to the lens housing, this will give you something to hold onto when returning the lens housing to the laser unit.

Make sure the Aperture Nozzle is seated squarely into the groove on the Lens Housing.

Step 9:

Re-insert the lens unit into the heatsink. It is important to ensure the small indentation in the Lens Housing is vertically aligned with the setscrew before tightening it.

Step 10:

Once complete, run the optics calibration once more as the focal point of your laser may have shifted slightly.