Being very interested in laminating materials to form composites, this project by fabtextiles caught my attention

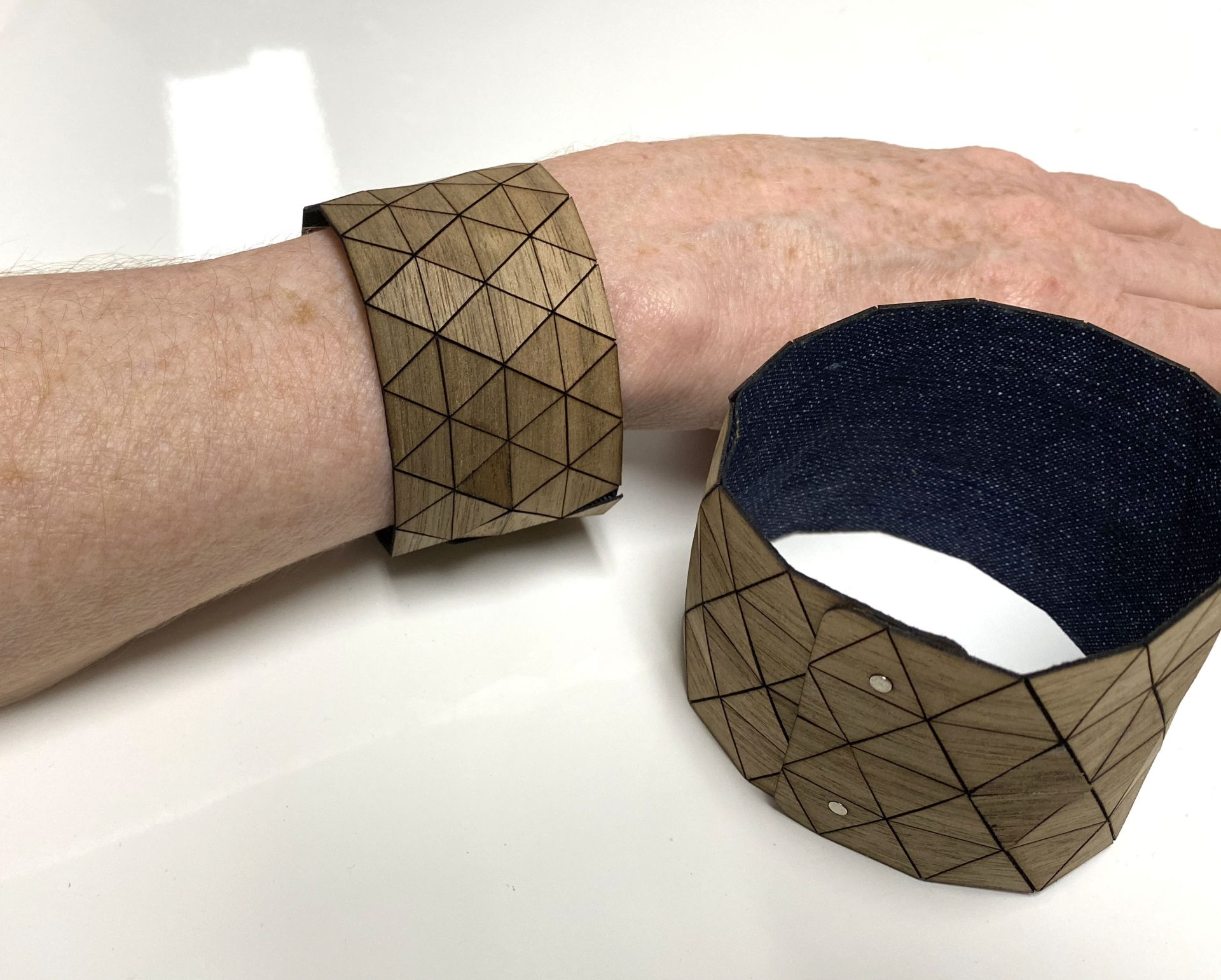

The lamination process involves gluing materials together whose properties compliment each other. In this case, the wood veneer acts as the aesthetic part of the bracelet and the fabric is flexible and holds it all together.

A vacuum press is often used to make laminates, but weighing the material down while the glues dry would also work. Pressure between the materials while drying ensures a good solid joining of the materials.

Project Files

Materials:

- Fabric, such as denim

- Thin wood veneer

- Small magnets

Other Items Needed:

- Glue

- Vacuum sealer/food sealer + bags (Optional, weight on the materials as they dry also works)

The Build

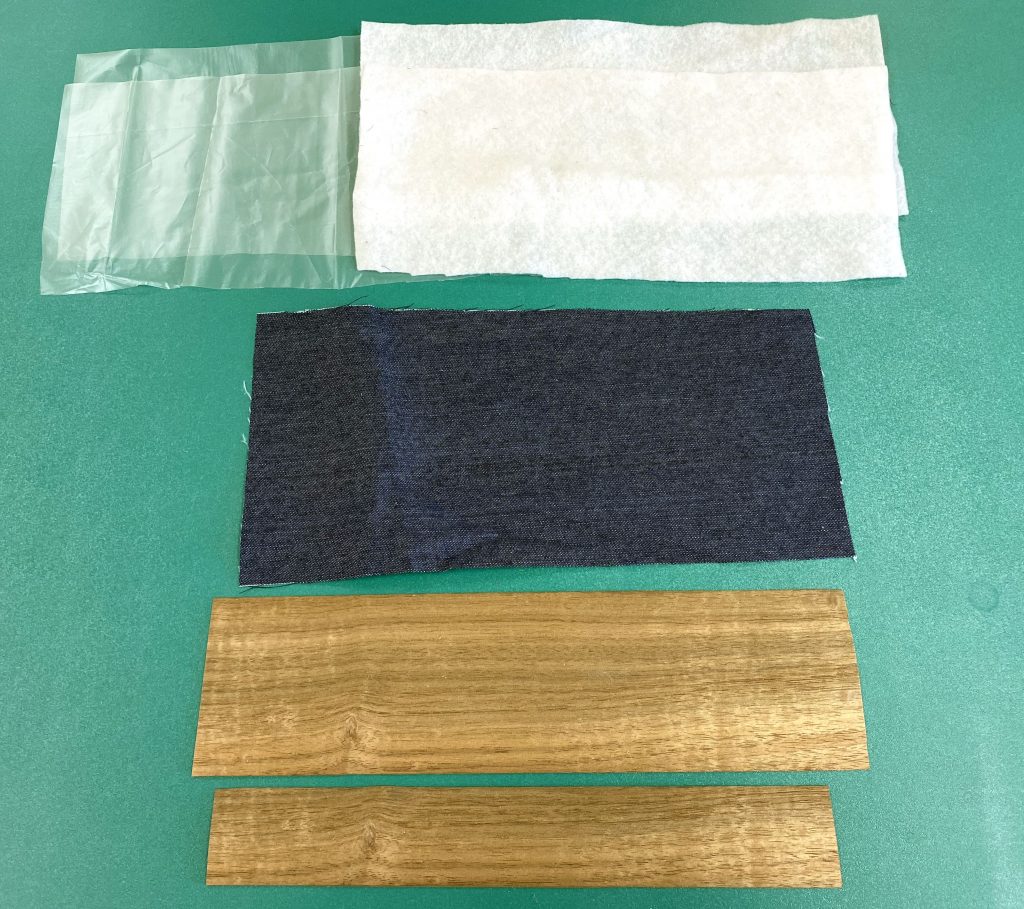

The first part of this project was to create the laminated material. I chose a piece of denim fabric for one side of the laminate and a thin wood veneer for the other.

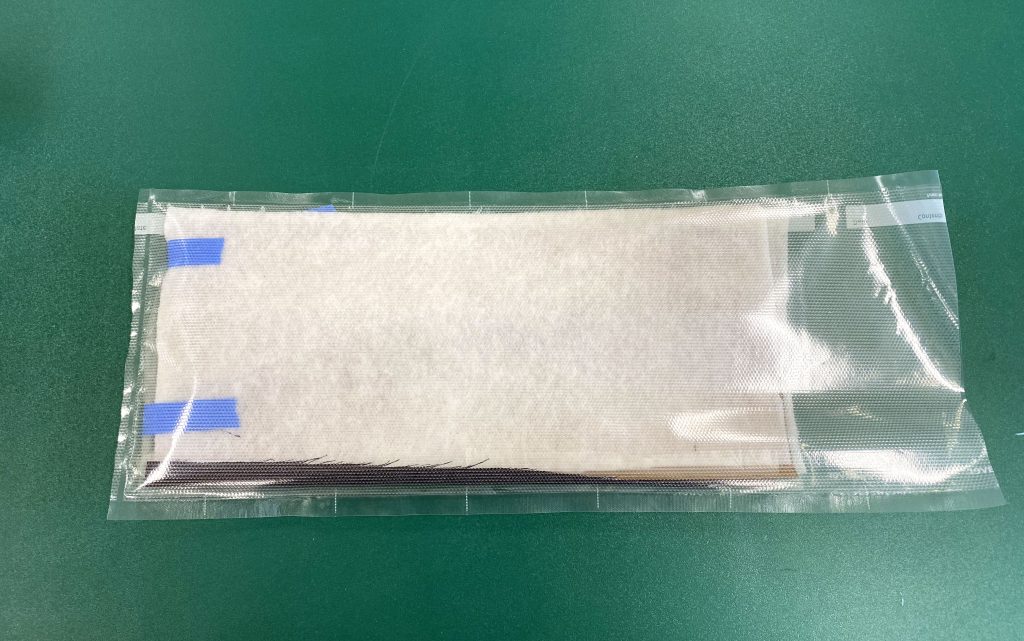

These materials will be glued and sandwiched together under pressure. To help with the lamination process I also used two pieces of soft fabric to act as the ‘breather’. This material will help extract all the air during the vacuum process.

I also used some sheets of plastic to prevent the breather fabric sticking to the laminated materials.

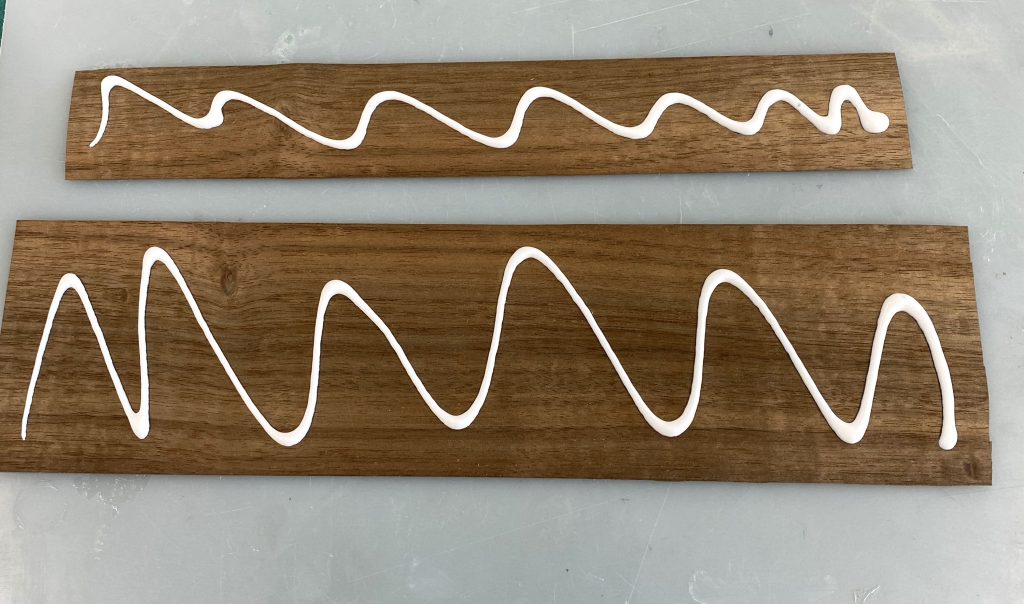

I first applied glue to one side of the veneers. It was important to ensure the entire surface of the veneer was covered with glue.

I then placed the glued veneer face on top of the denim fabric.

I created a sandwich of the materials in this order from the bottom up.

1: Breather cloth, 2: Plastic, 3: Denim, 4: Glued Veneer, 5: Plastic, 6: Breather cloth.

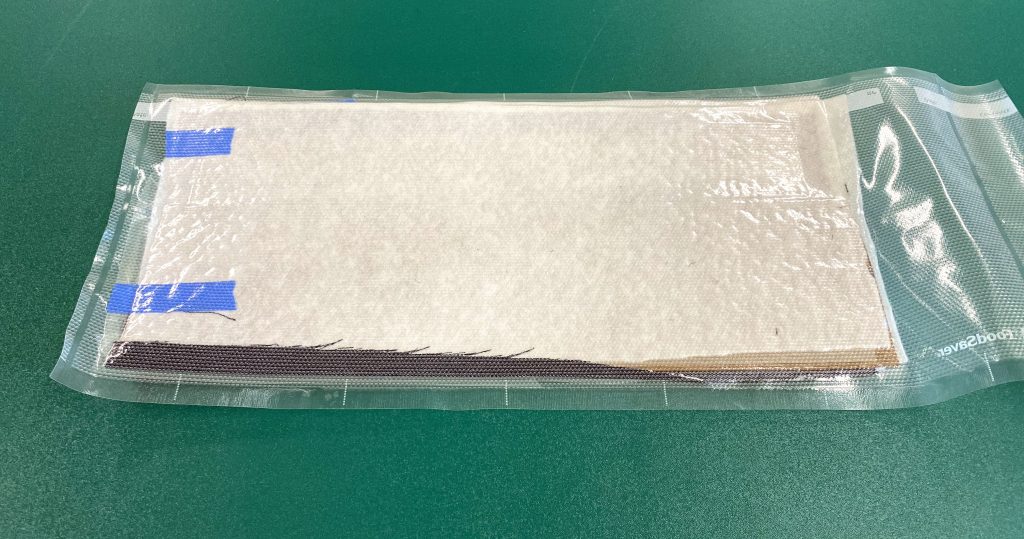

This sandwich of materials were then placed into a food sealing vacuum bag and a food vacuum machine was used to extract all the air from the bag.

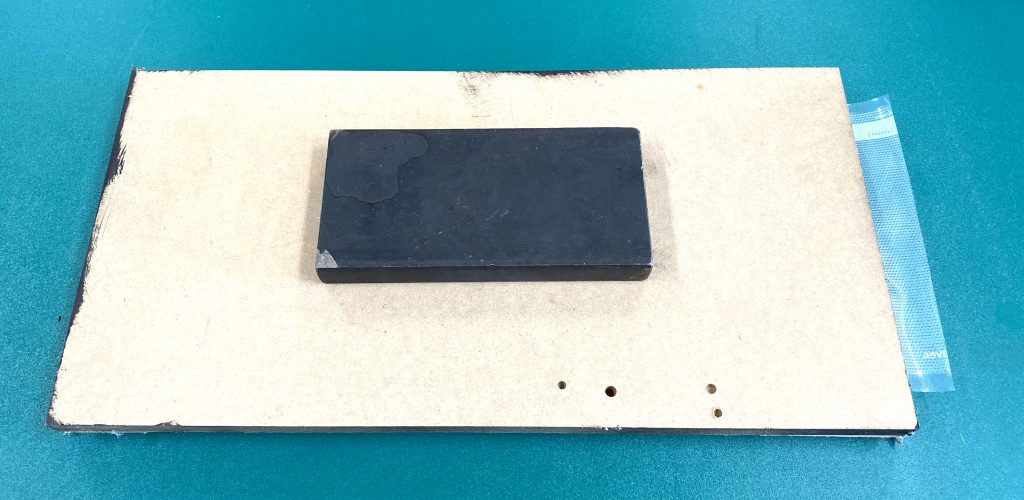

To keep the materials flat while the glue dried, I placed the bag between some wood and weighed it down.

After 12 hours of drying I removed the materials from the bag and checked they had been well stuck together.

Note, that the first time I did this I discovered that the glue I had used did not form a good bond between the denim and veneer. After redoing with a different glue, it worked very well.

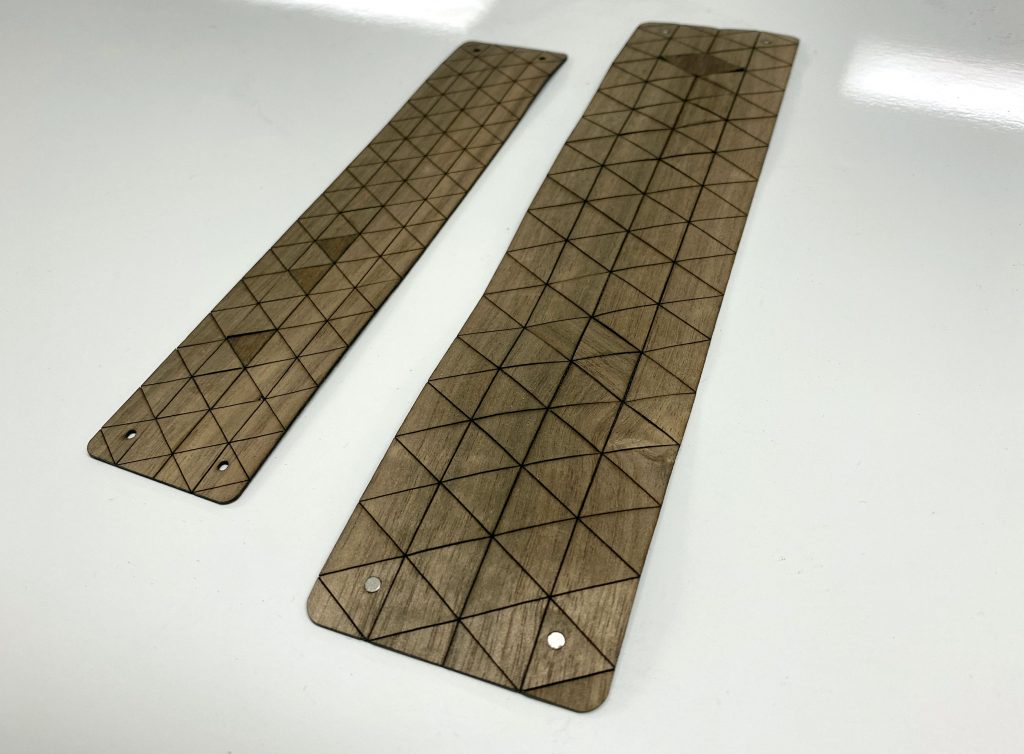

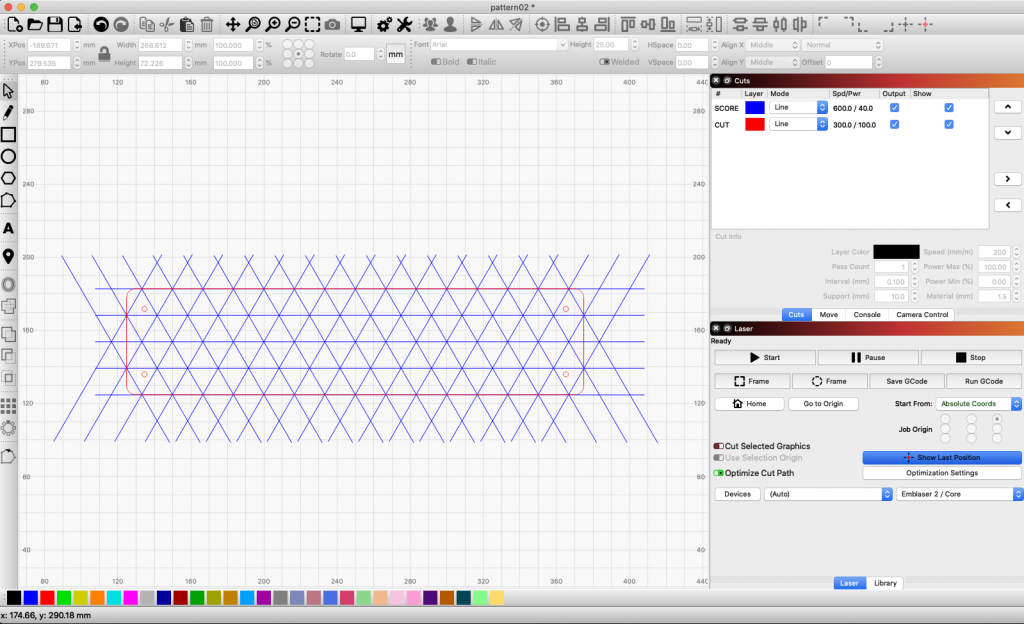

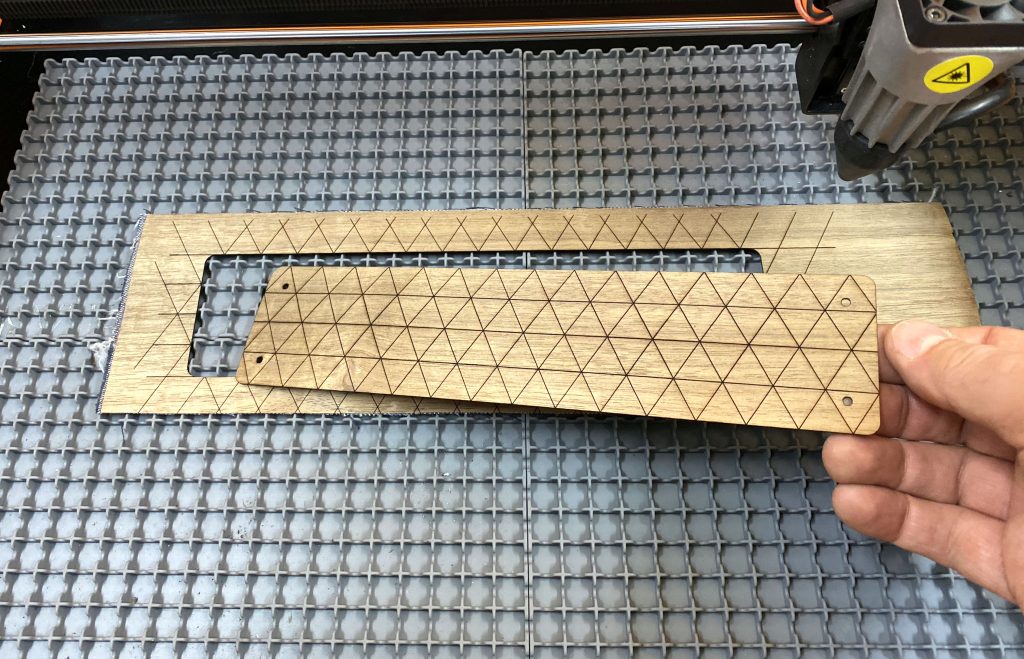

In LightBurn I created a simple triangular design for the bracelet, similar to the original project article.

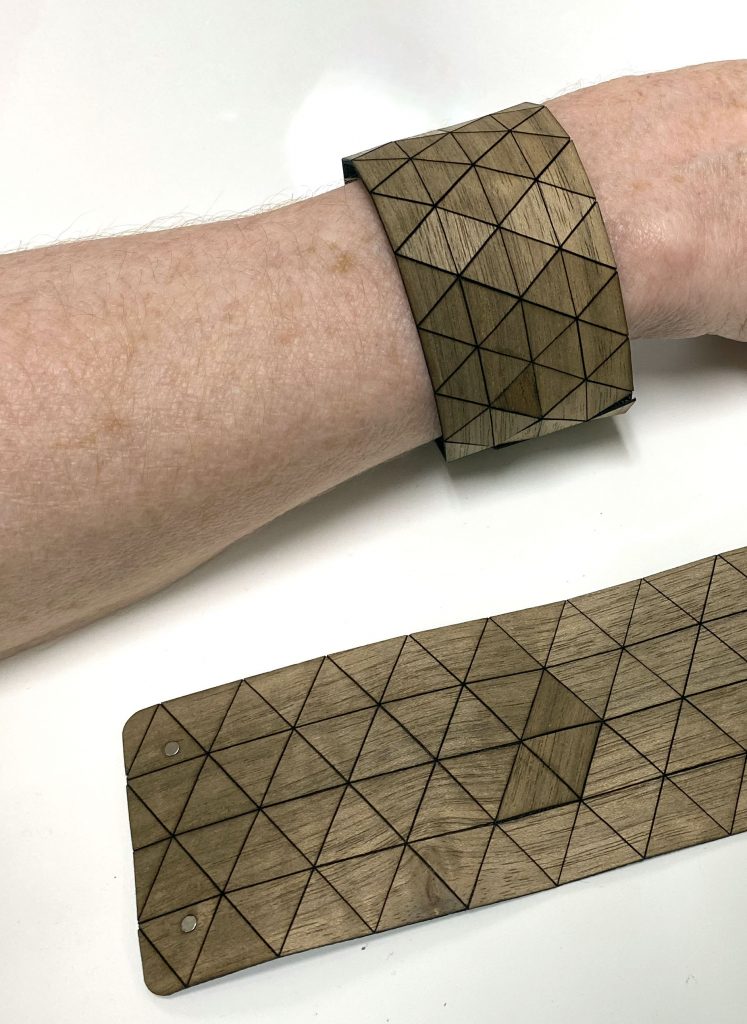

The key to the laser cutting was to ensure the design was only cut into the wood veneer and not through the fabric. A little testing gave me the appropriate laser speed and power settings.

Finally I inserted some small magnets to help hold the bracelet together while it’s being worn. Make sure you get the magnets the right way around before glueing them in!