Here are the steps needed to replace the existing 5w laser unit with the 10w version.

Please follow them carefully and contact us if you run into any problems: help@darklylabs.com

Tools Needed:

- 10W laser Unit

- Metal bracket & plastic belt plate (attached together)

- 1x M3x35mm bolt

- 3x M2x5mm screws

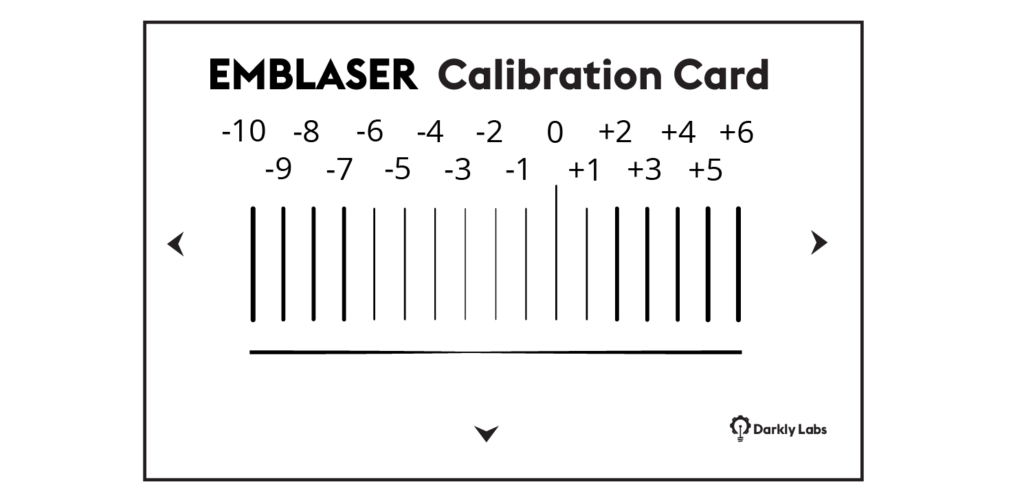

- Focus Calibration card

- Torx T10-Security tool

- Philips PH1 tool

- Hex 2.5mm tool

- Hex 1.3mm tool

Note: Your 10w laser upgrade is supplied with these required parts and tools.

Step 1:

Before you start this replacement, please make sure your laser is at the top of it’s movement. This is easily done by turning your machine on and letting it ‘home’ itself.

*** IMPORTANT: Please make sure you turn your machine off and power unplugged before proceeding ***

Removing the Silicone Nozzle is also recommended.

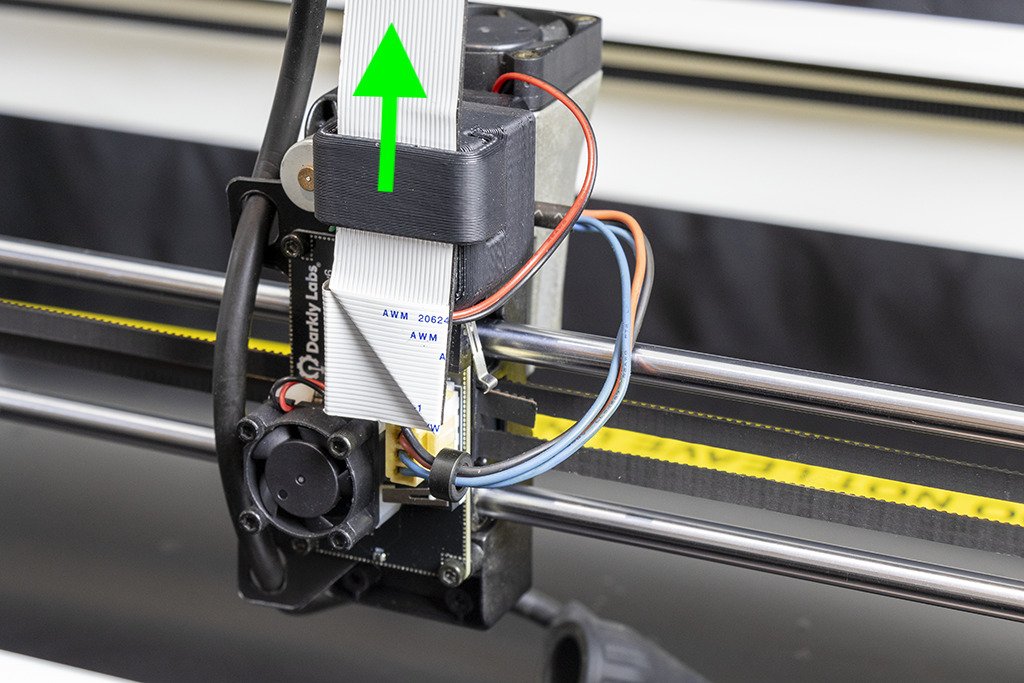

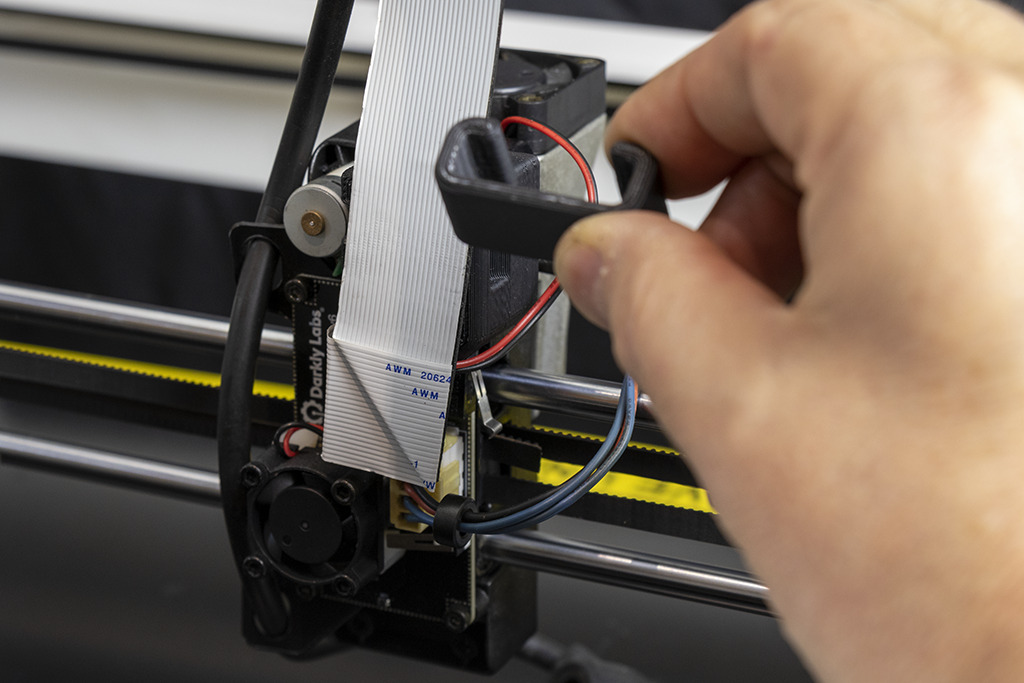

Step 2:

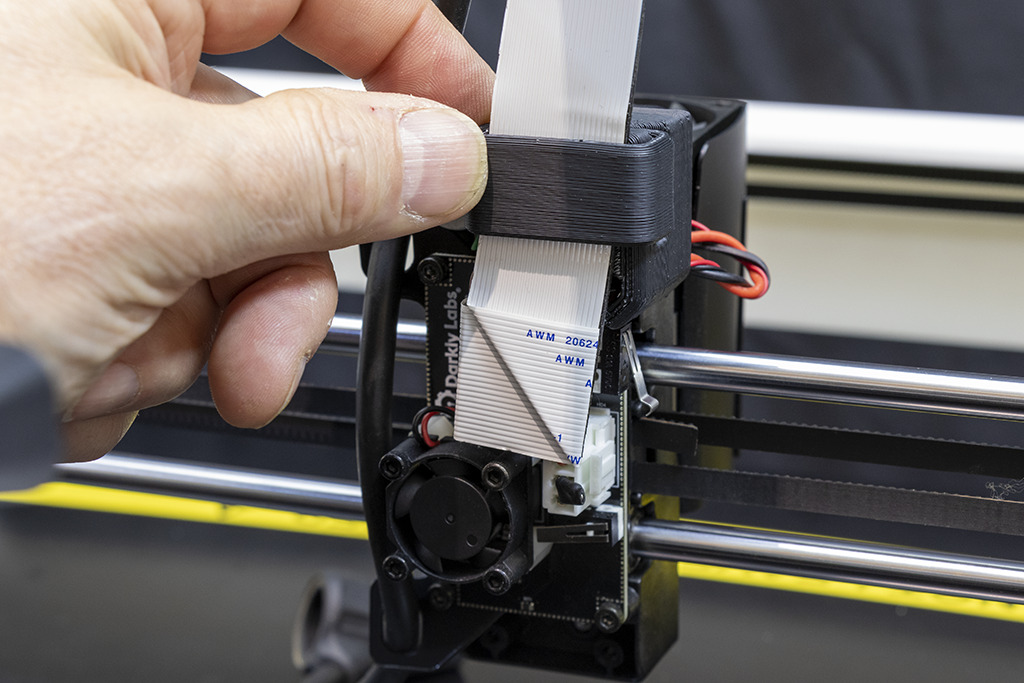

Slide off the FFC clip.

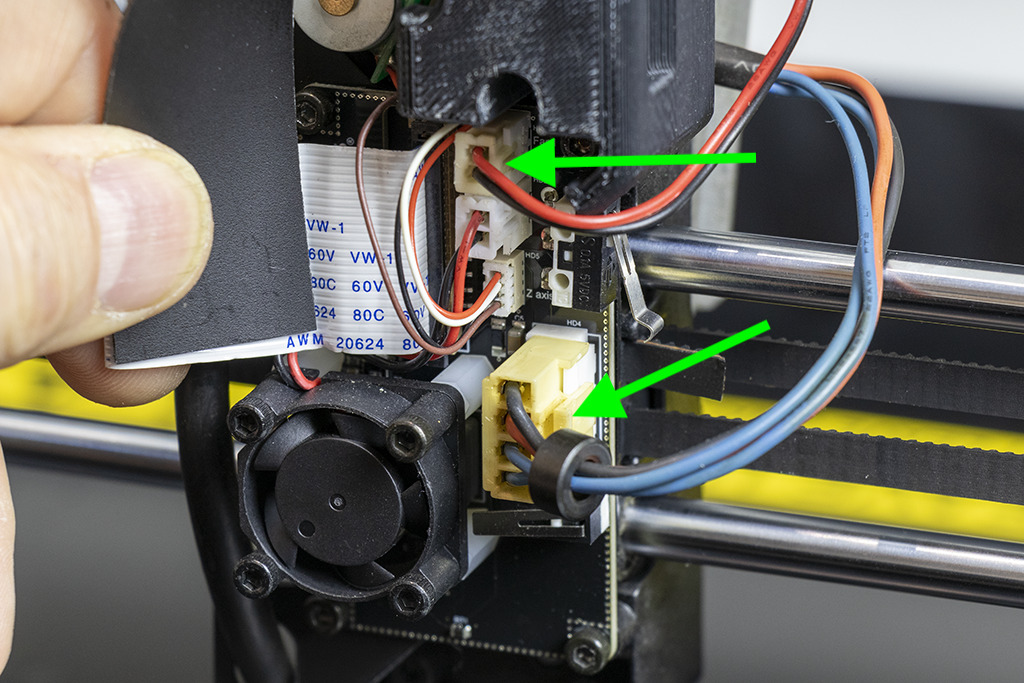

Step 3:

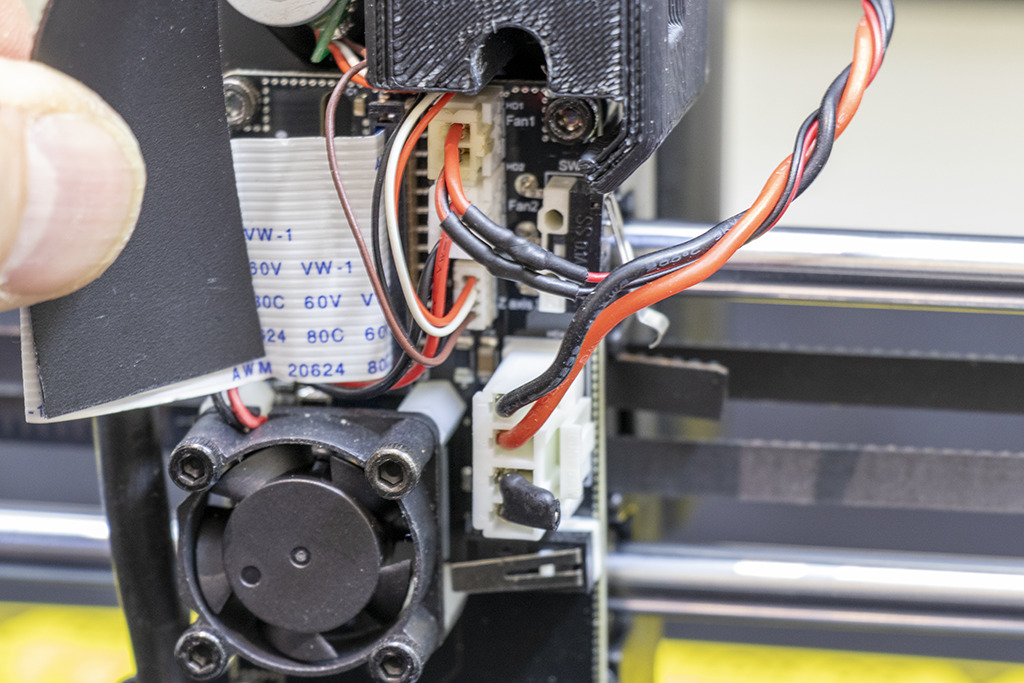

Carefully unplug the Laser Unit and Fan connectors.

Please note that the Laser Unit connector has a clip that needs to be depressed for the connector to unplug.

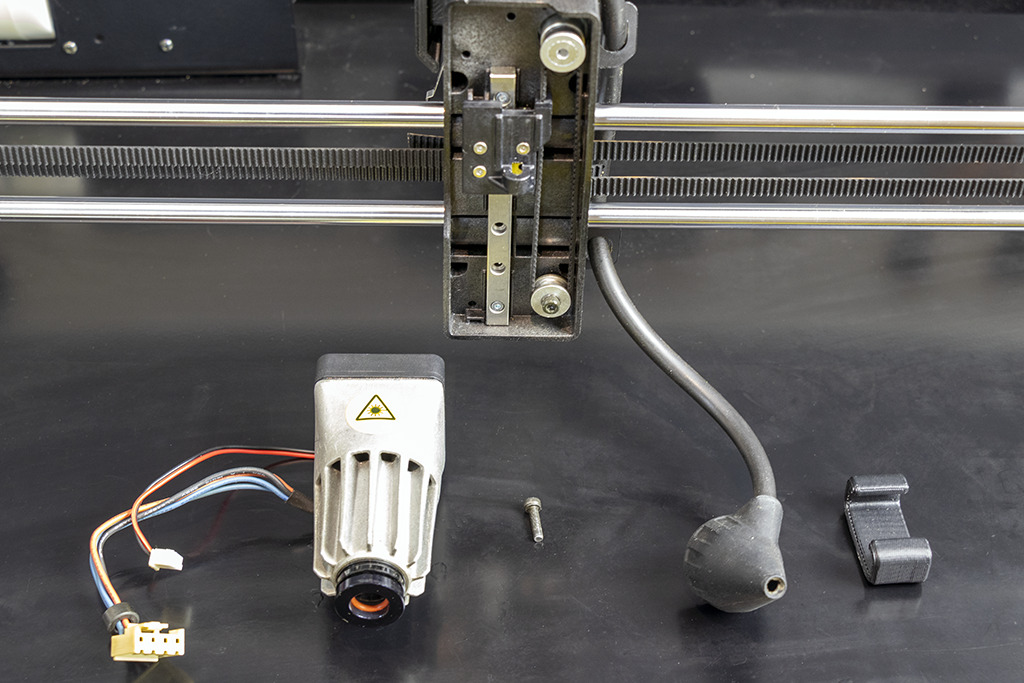

Step 4

Use the Torx T10-Security tool to unscrew the bolt holding the 5w laser unit in place.

When you are looking down from the top, turn the tool clockwise to undo the bolt.

Once the bolt has been removed, slide the laser unit upwards to release it fro the bracket.

Step 5

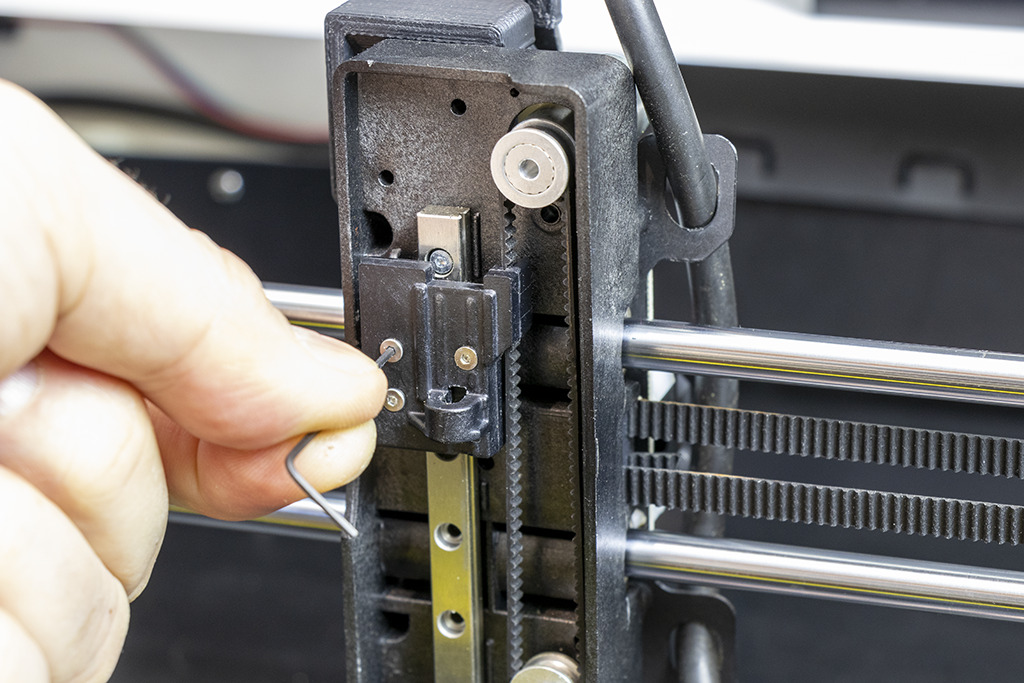

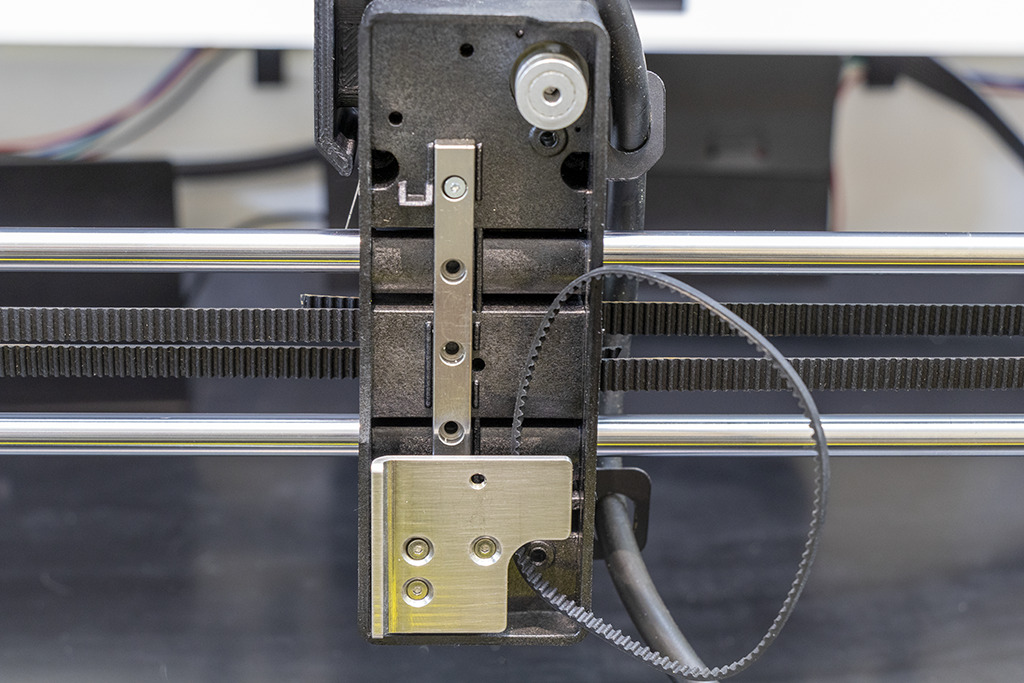

Using the Hex 1.3mm tool, carefully unscrew the three screws holding the belt plate in place.

IMPORTANT: These screws are delicate and need careful handling. Turn the tool counter-clockwise to unscrew.

NOTE: Some units have a pieve of black felt over the top right side screw. If you have this, remove the felt to access the screw beneath it.

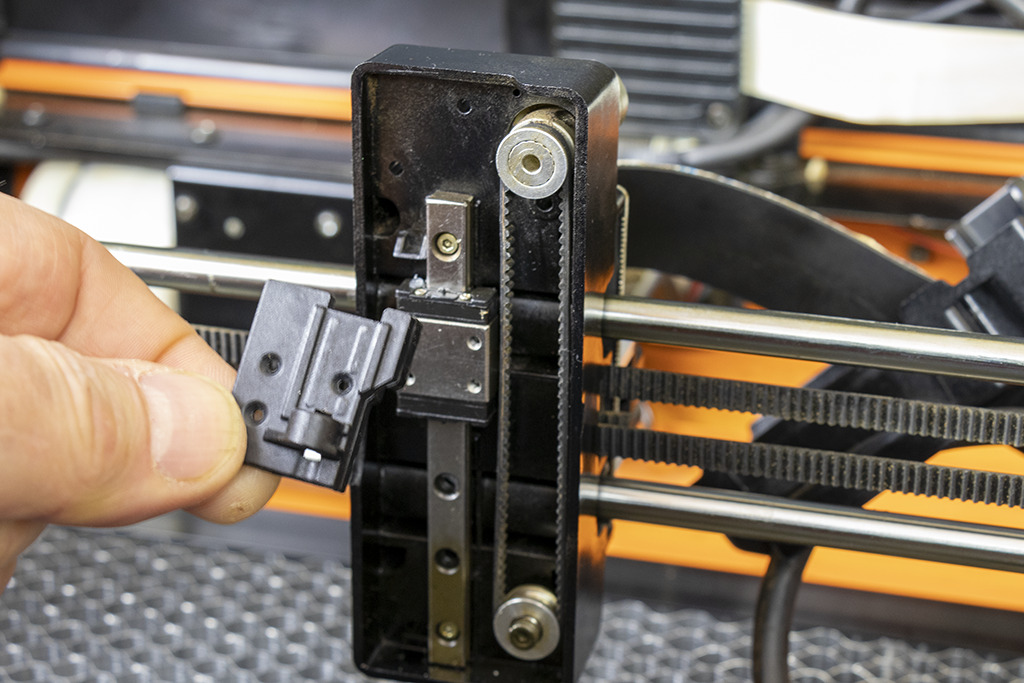

Step 6

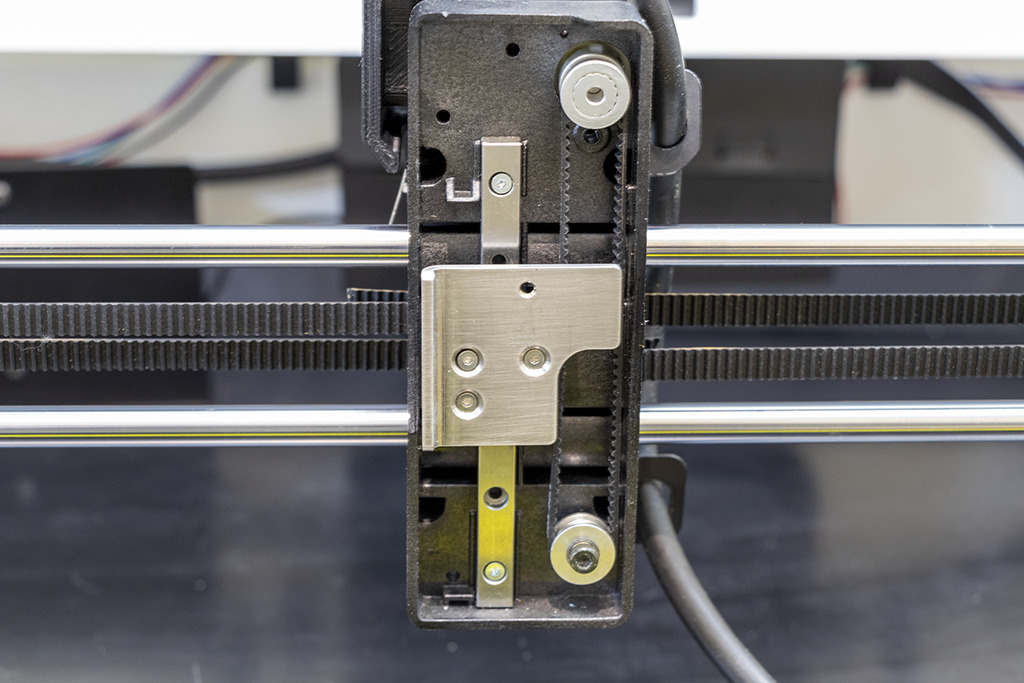

Using the Torx10-S or 2.5mm Hex tool, unscrew the bolt holding the lower belt pulley in place.

Step 7

With the lower pulley removed, slide out the belt and insert ito into the new belt plate as shown in the photo below.

NOTE: The new metal bracket and plastic belt plate have been attached together with double sided tape to make assembly easier.

Step 8

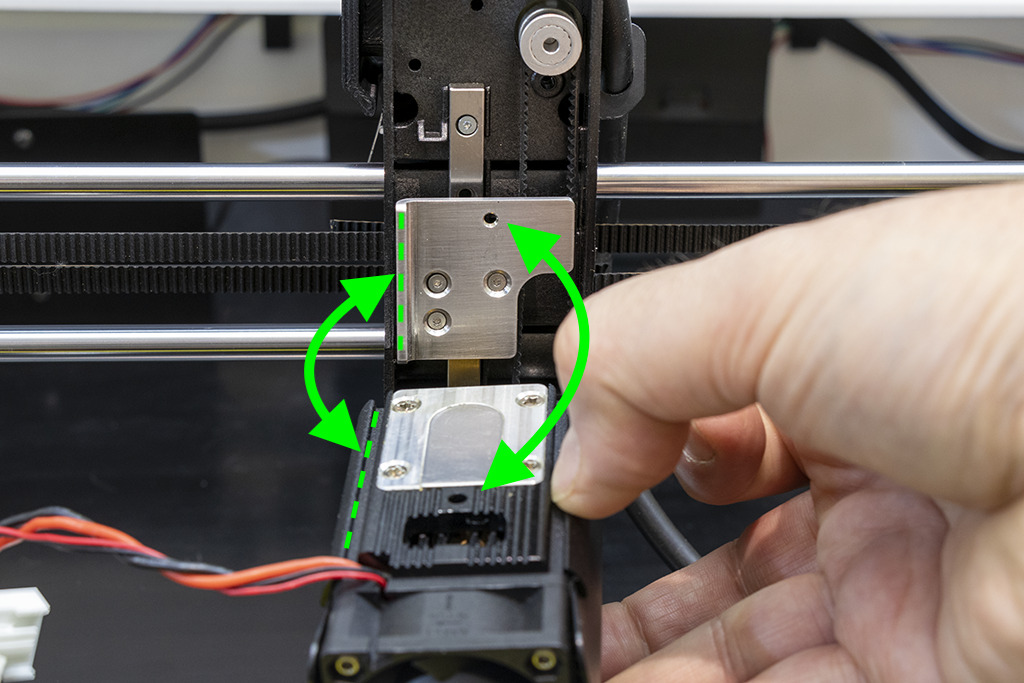

Using a new set of M2x5mm screws supplied with your kit, install the new metal bracket and belt plate.

IMPORTANT: The M2x5mm screws are VERY delicate. Work slowly and tighten them carefully. Do not tighten them excessively.

Once attached, slide the belt over the top motor pulley and then re-install the lower belt pulley.

Intermission

If you have made it this far, give yourself a pat on the back.

All the hard work is done.

Take a few minutes to have a cup of coffee or tea and think about all the amazing projects you will be able to create with your new laser unit.

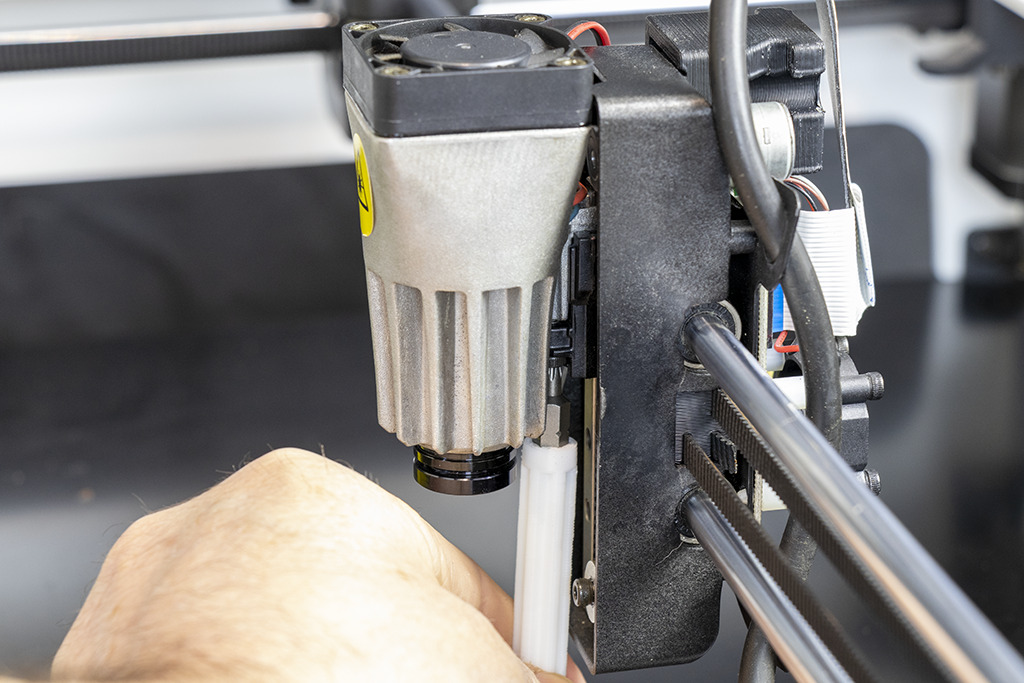

Step 9

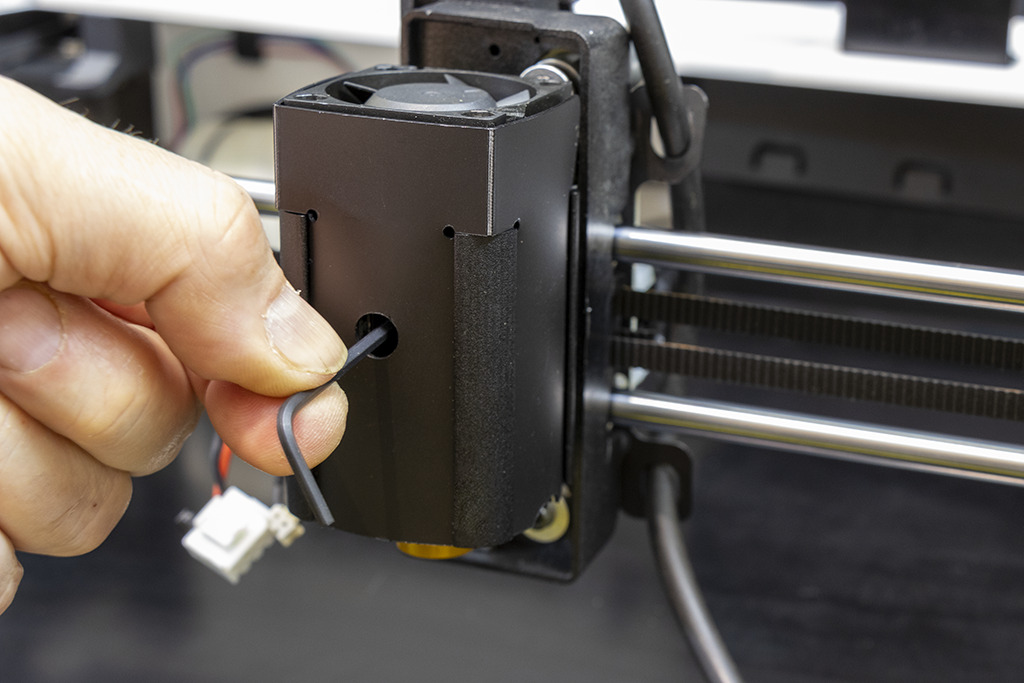

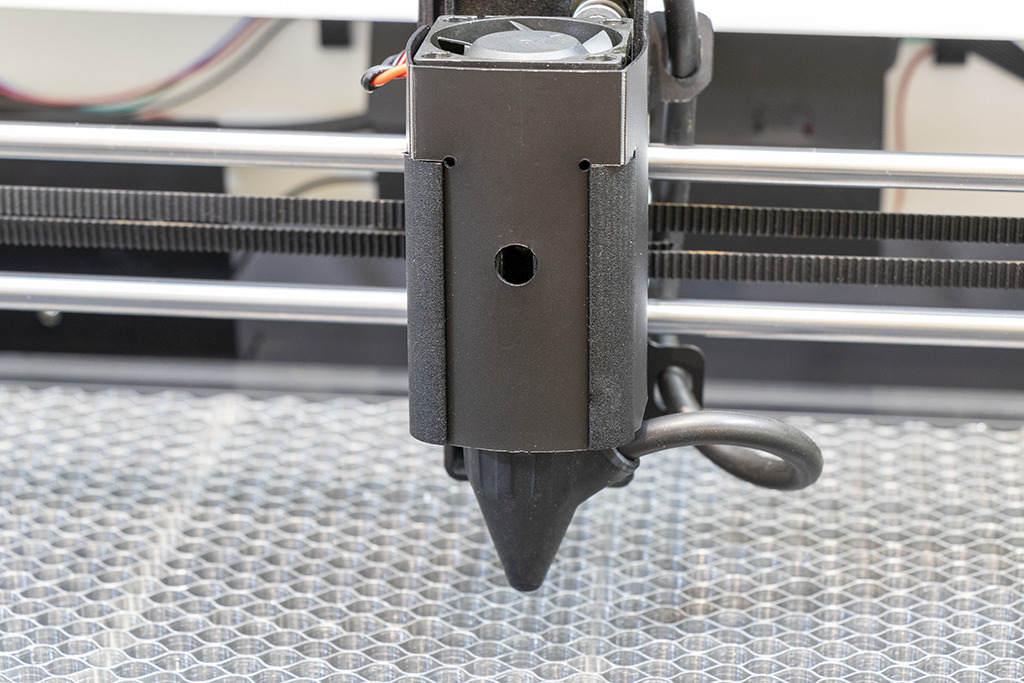

It’s now time to install the 10w laser unit.

Note the slot on one side and screw holes that should match up.

Insert the M3x35mm screw into the front of the laser unit and attach it to the hole in the metal bracket using the Hex 2.5mm tool.

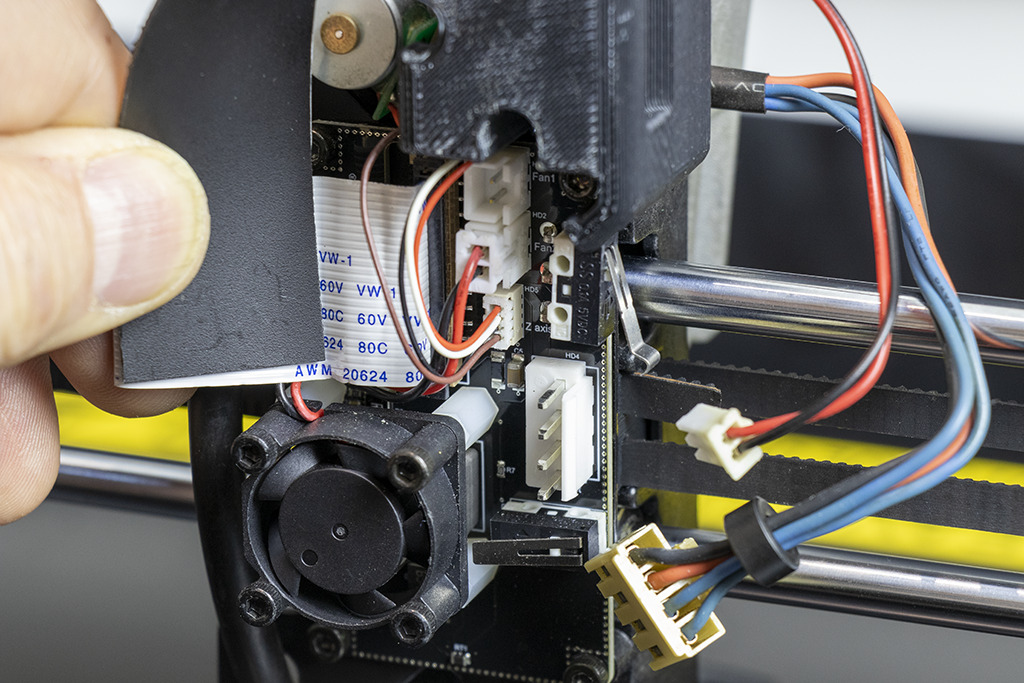

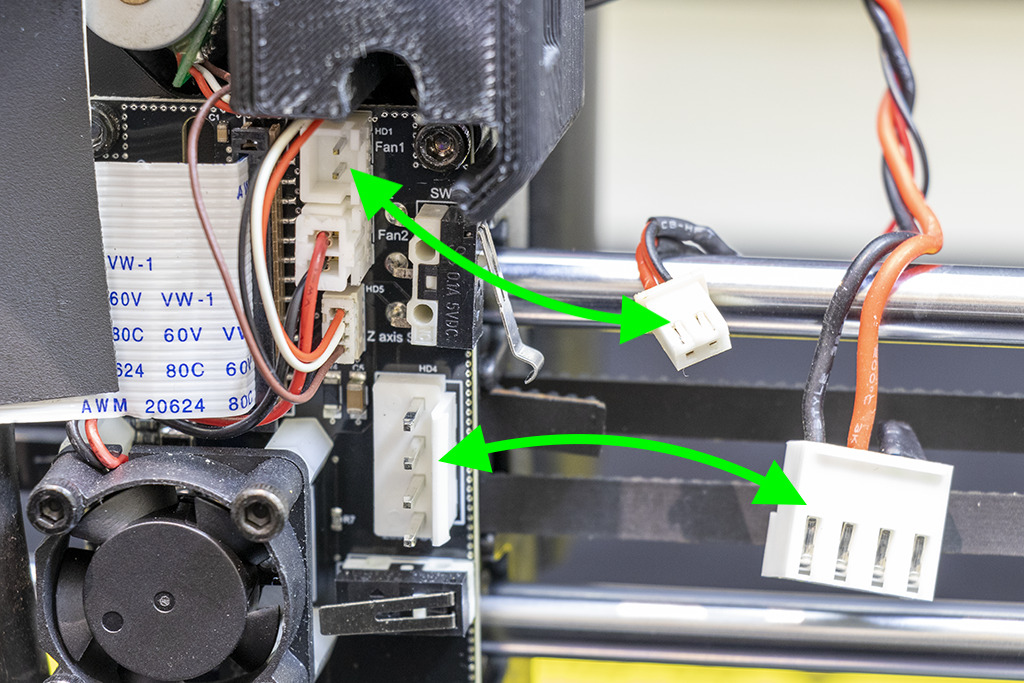

Step 10

Plug the Laser and Fan connectors into the Laser Driver PCB.

Step 11

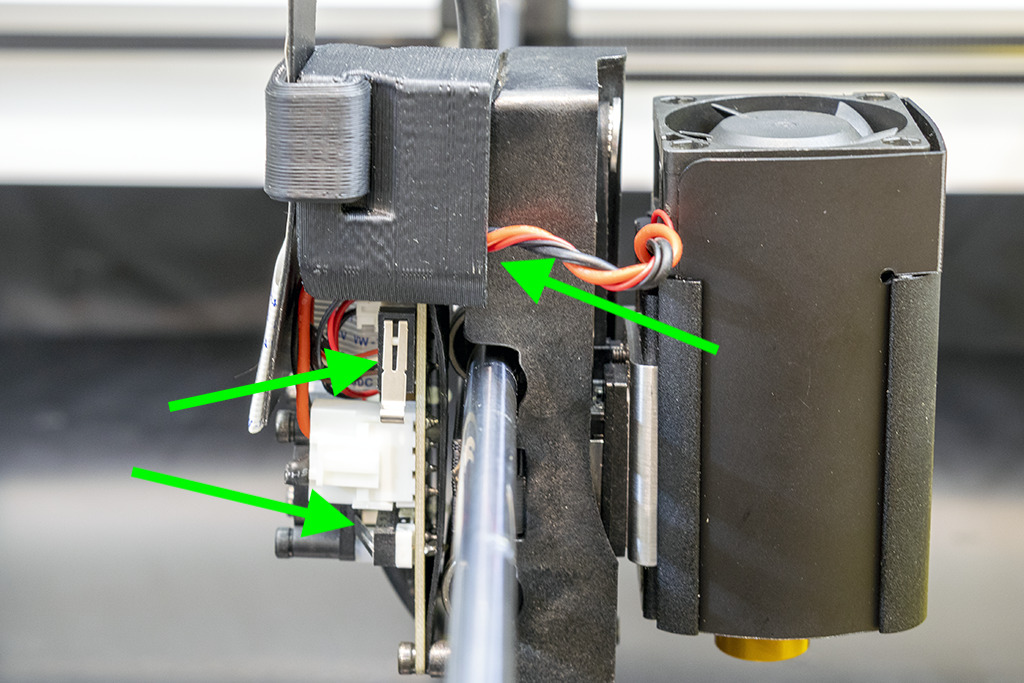

Slide on the FFC clip.

Make sure the wiring exits the cover as shown in the photo and nothing is obstructing the limit switches.

Step 10

Using the supplied cards, run the ‘Focus Calibration’ process in LightBurn before using your new laser unit.

Step 11

Re-attach the Silicone Nozzle.

*** IMPORTANT ***

To ensure you are taking full advantage of your new 10w laser module and reducing the risk of material fire, Download and install the 10w Material Library into LightBurn.

You can find the 10w Material library here: LINK