Over time the rails and bearings in your machine will accumulate dust and debris. It’s important to keep them clean so they can allow your Emblaser Pro to operate correctly.

Dirty rails may result in the following issues:

- Incorrect machine homing.

- Incorrect z-axis movement.

- Incorrect maser movement.

Step 1:

Make sure your machine is switched off.

Step 2:

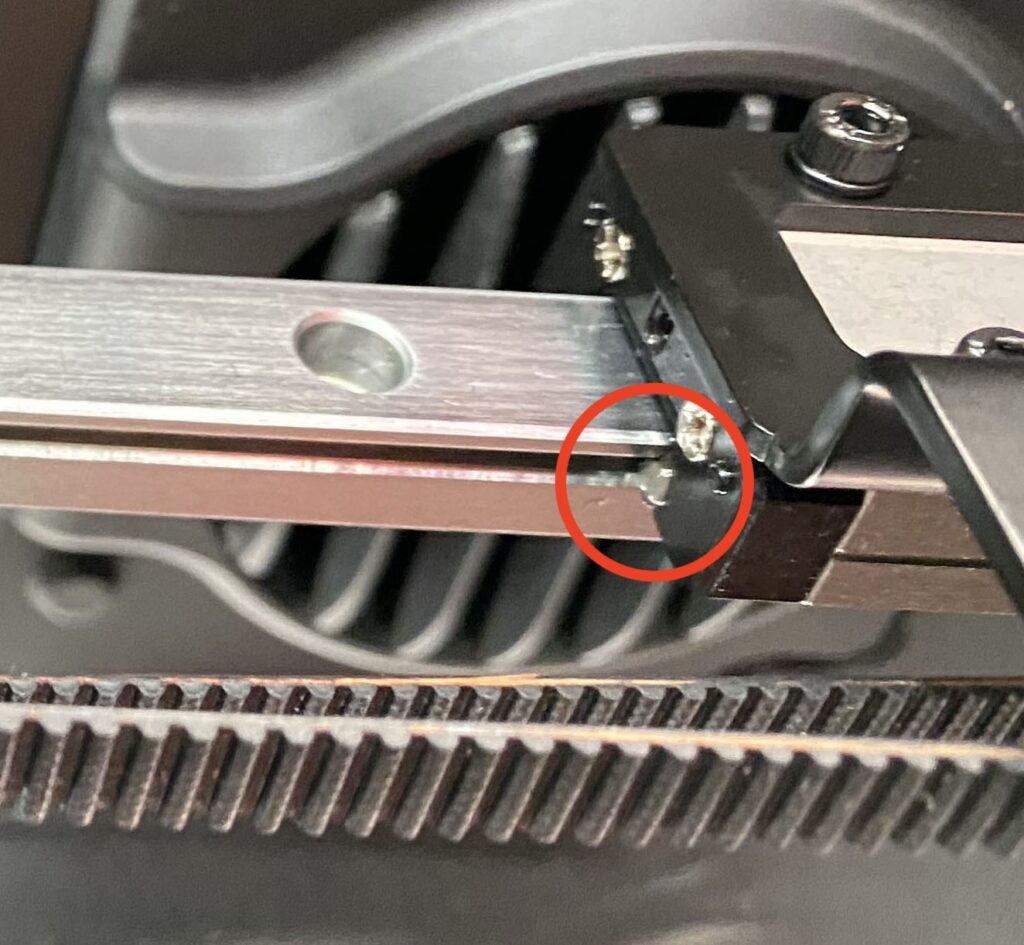

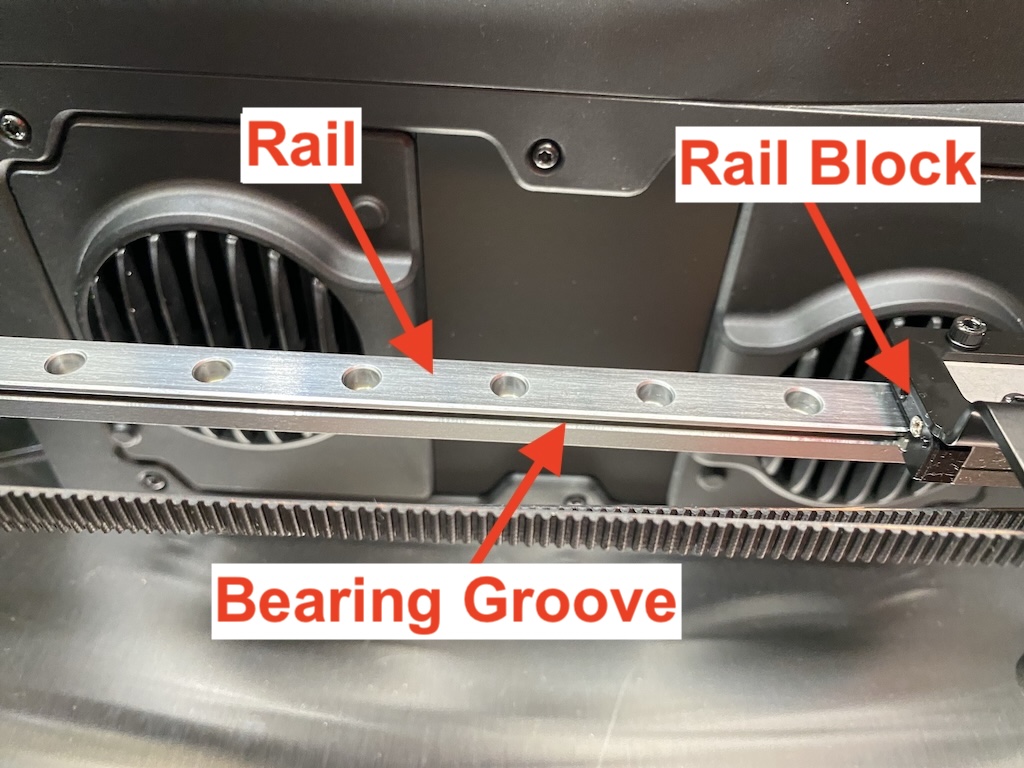

From the image below, please note that the ‘bearing groove’ is the part of the rail the rail block rides along.

The ‘bearing groove’ is the main section that needs to be kept clean and lubricated.

Adding lubricant to any other part of the rail will only cause the accumulation of dust and debris.

Step 3:

Using a Q-Tip, clean the bearing grooves on all the rails. Remember that there are 2 groves on each rail, one on either side.

Make sure you push the Q-Tip into the groove to ensure you are cleaning is fully.

Step 4:

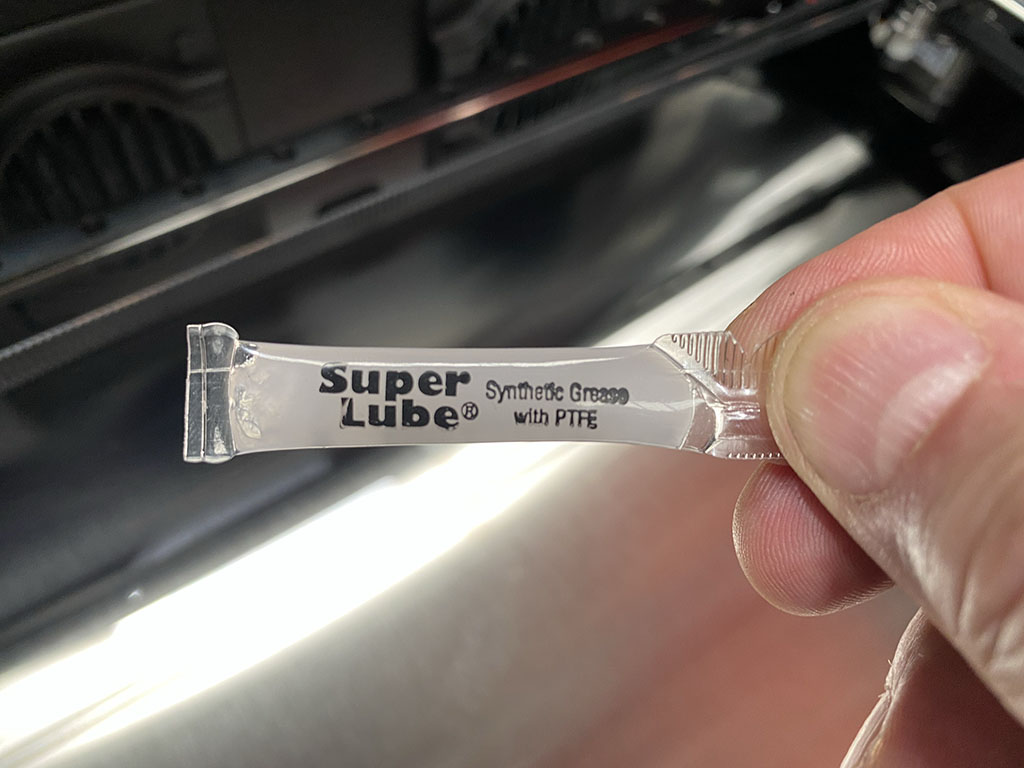

Use a synthetic grease on the rails and bearings.

Apply a small amount to a clean Q-Tip and work it into the bearing groove on all the rails.

A small amount spread over the length of the rail is all that is needed. Do not completely fill the groove with grease.

Step 5:

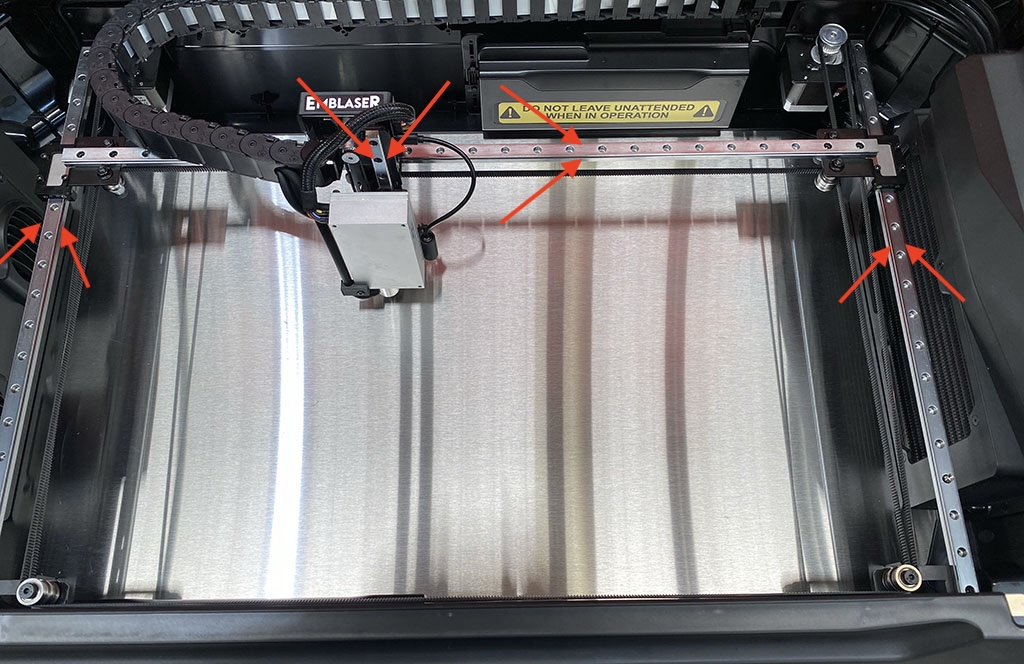

Make sure you clean and lubricate all 4 rails in your machine.

Step 6:

Slowly move the laser around all areas of the workspace to ensure the bearings have been lubricated and grease distributed.

If there is a lot of visible grease built up on the bearing blocks, wipe it away. This buildup will only gather dust and debris.